A Complete Guide to 6K Polishing Machines for Metal Coil Processing

A 6k polishing machine for metal coil processing helps you make stainless steel coils very shiny. This machine removes scratches and makes the surface smooth. It can give finishes like 2B, No.4, and the bright 6K mirror finish. Many factories use this process because it meets strict quality rules. It also makes coils look clean and nice. If you pick the right machine, you can work faster and make better metal coils.

Key Takeaways

- A 6K polishing machine helps make stainless steel coils smooth and shiny. It removes scratches and makes them look better. This also improves their quality.

- The machine works by itself and uses many polishing heads. This saves time and lowers labor costs. It also gives the same results every time.

- Using the right abrasives and steps helps get a bright 6K finish. This finish meets high quality rules.

- Picking a machine that matches your coil size and needs helps you work faster. It also stops problems during polishing.

- Doing regular maintenance and following safety rules is important. Careful use keeps the machine working well. This gives you the best metal coil finishes.

6K Polishing Machine for Metal Coil Processing

Definition

A 6k polishing machine helps make stainless steel coils look better. You can use it on coils made from 201 or 304 stainless steel. These types are part of the 200 and 300 series. Factories use these coils a lot. The machine gives the coils a shiny finish like 6K, 2B, or mirror. You often see these finishes in things like kitchenware, elevators, and panels.

This machine takes away scratches and makes the surface bright. The 6K finish is not as smooth as 8K or 12K. But it still makes the coil shiny and smooth. This process also helps the coil fight rust and slide more easily.

Core Functions

The 6k polishing machine does many important jobs. It helps with deburring, grinding, and finishing metal coils. The machine works by itself, so you do not need to polish by hand. It can polish all sides of a coil at once. You can change the polishing wheels to get different looks, like removing burrs or making a mirror finish.

- The machine makes the surface brighter and shinier.

- It helps the coil resist rust.

- You can use cloth or nylon wheels for each step.

- The machine can have 4 to 64 polishing heads to work faster.

- It has dust covers to keep the air clean and protect people.

- Automation saves money and makes work faster.

These features help you meet tough quality rules. The machine makes sure every coil looks good and follows national standards.

Role in Processing Lines

You will find the 6k polishing machine in modern production lines. It comes after the coil is cut or rolled. The machine gets coils ready by making them smooth and shiny. You can connect it to other machines, like cleaning or checking units, to make a full line.

Using this machine helps your coils meet national rules for surface quality. It also makes your products look and work better. Many companies use this machine to give customers great stainless steel coils.

Features and Specs

Technical Specs

6K polishing machines have many helpful features. These features help you get great results. Here are some important technical specs:

- Stainless steel heating parts heat the machine evenly. This helps the machine work better.

- The machine uses strong steel plates. These plates can handle high heat and do not rust.

- A good vacuum pump keeps the machine running well. It also helps the machine last longer.

- Digital controls make the machine simple to use. The machine can do many things by itself.

- There are two work tables. This saves time and stops heat from being wasted.

- The work table is made from tough steel. It does not bend when it gets hot.

- The machine heats up fast and pulls air well. This helps make the coils smooth and shiny.

- An automatic cooling system keeps the coils safe. It also helps the coils stay high quality.

- The machine often uses a 15L vacuum pump. This gives it strong suction power.

These features let you polish coils fast and safely. You can also meet strict quality rules.

Polishing Stages

A 6K polishing machine works in a few steps. These steps turn rough coils into smooth, shiny ones. Each step has its own job:

- Rough polishing: Six grinders take off rough spots and burrs. This makes the coil smoother.

- Fine polishing: Wool felt and polishing slurry are used. They remove oxide layers and sand marks. The coil starts to shine and reflect light.

- Washing and drying: Brushes and clean water wash the coil. Baking lamps dry it so no water stays.

- Quality inspection: You look for blisters, dark spots, or scratches. This makes sure every coil is good.

- Final packing: A film covers the coil. Careful packing keeps it safe when shipped.

Each step takes away more defects and makes the surface better. You get a 6K finish that is shiny and smooth, but not as perfect as higher mirror grades.

Abrasive Materials

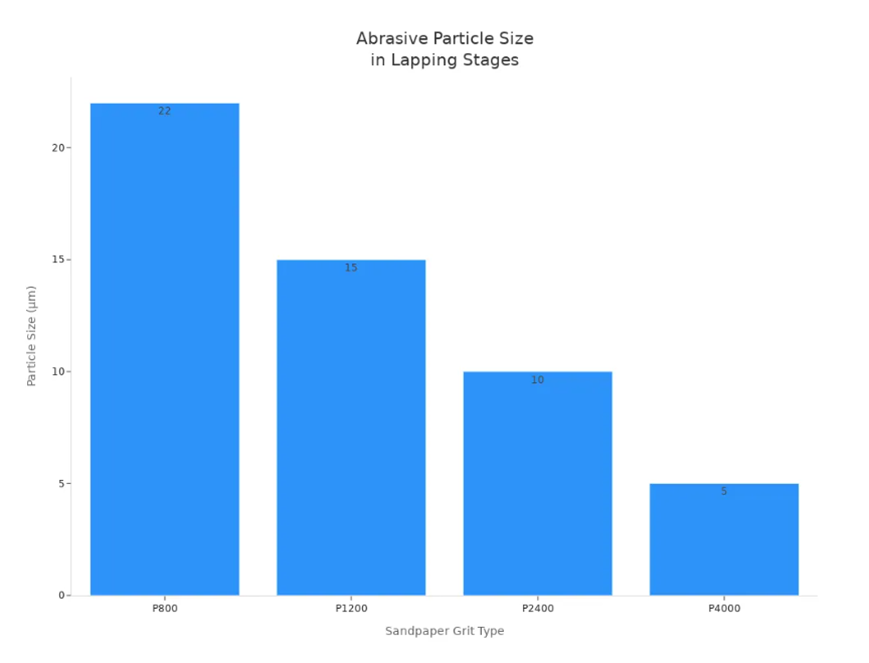

You need the right abrasives to get the best finish. Different materials and sizes are used at each step. The table below shows common abrasive types and how they help:

|

Abrasive Material Type |

Particle Size (Average Diameter) |

Process Stage |

Impact on Polishing Process |

|

PSA Silicon Carbide Sandpapers |

P800: 22 µm |

Lapping |

Removes material quickly |

|

P1200: 15 µm |

Lapping |

||

|

P2400: 10 µm |

Lapping |

||

|

P4000: 5 µm |

Lapping |

||

|

Diamond Abrasives |

Various smaller sizes |

Polishing |

Makes the surface smoother and reduces roughness |

|

Silicon Dioxide Abrasives |

Various smaller sizes |

Polishing |

Used from rough to final polishing for high surface quality |

You start with bigger particles to take off more material. Then you use smaller abrasives to make the surface smoother and shinier. Picking the right abrasive helps you control how shiny and smooth your coil gets.

Benefits

Surface Quality

You want your stainless steel coils to look smooth and bright. The 6k polishing machine for metal coil processing helps you reach this goal. This machine removes scratches, pits, and marks from the surface. You get a shiny finish that meets national standards. Many industries need this high level of surface quality. For example, kitchenware and elevator panels must look perfect. When you use this machine, you can make your products stand out.

Tip: Always check the coil after polishing. You can spot any small defects early and fix them before shipping.

Efficiency

You can save time and effort with this machine. The 6k polishing machine for metal coil processing works much faster than manual polishing. You do not need to stop often to change tools. The machine can polish many coils in a short time. Automation lets you set the process and focus on other tasks. You also use less energy and reduce waste. This means you can finish more work in less time.

- You increase your daily output.

- You lower your labor costs.

- You keep your production line moving smoothly.

Consistency

You want every coil to look the same. This machine gives you steady results. Each coil gets the same finish, no matter how many you polish. The settings stay the same for each batch. You do not have to worry about human error. Your customers will notice the quality and trust your products.

Note: Consistent quality helps you build a strong reputation in the market.

How It Works

Polishing Process

You start the polishing process by preparing the stainless steel coil. The 6k polishing machine for metal coil processing uses a series of steps to remove scratches, pits, and oxidation. First, you feed the coil into the machine. The machine uses rough grinding wheels to take away deep marks and burrs. These wheels work fast and cover the whole surface.

Next, you switch to finer wheels and mops. These tools smooth out the surface even more. You use special compounds made for stainless steel. These compounds help the wheels polish the metal and make it shine. The machine keeps the coil moving so every part gets the same treatment.

After polishing, you wash the coil with clean water. Brushes remove any leftover dust or compound. Drying lamps make sure the coil is dry before you check it. You inspect the coil for any spots or scratches. If you see any problems, you can fix them before packing.

Tip: Use the right compound and wheel for each step. This helps you get a smooth, shiny finish every time.

Setup and Operation

You need to set up the machine before you start. First, check that all wheels and mops are in place. Make sure you use the right type for the finish you want. For a mirror finish, use soft cloth wheels and fine compounds. For a brushed look, use nylon or abrasive wheels.

Set the speed and pressure on the control panel. The machine has digital controls that make this easy. You can save your favorite settings for different coil types. Place the coil on the work table and secure it. Start the machine and watch as it polishes the coil.

You do not need to stand by the machine the whole time. The machine works by itself and stops when it finishes. You can check the progress through the dust covers. If you see any problems, you can pause the machine and fix them.

Note: Always check the wheels and mops before each job. Worn tools can scratch the coil and lower the quality.

Safety

You must follow safety rules when you use a 6k polishing machine for metal coil processing. Polishing creates dust and uses fast-moving wheels. Protect yourself and your team by following these steps:

- Wear safety clothing and a mask to keep dust out of your lungs, eyes, and skin.

- Do not breathe in the dust from polishing. It can harm your health.

- Make sure you mount buffing wheels with self-centering safety flanges and center reducer plates. This keeps the wheels secure.

- Never run buffing wheels above their rated speed. For example, 10″ x 3″ wheels should not go over 2,000 RPM. Running them at 5,000 to 6,000 RPM is risky and not covered by the manufacturer.

- Check buffing wheels for gaps. Some gaps are normal if the wheels are tight and secure.

- Keep the area clean and free from loose tools or parts.

Safety first! Always follow the machine manual and wear the right gear. This keeps you safe and helps your machine last longer.

Choosing a Machine

Selection Factors

When you choose a 6k polishing machine for metal coil processing, you need to look at several important factors. The size of your coils matters a lot. Machines have limits for coil width, thickness, and weight. Some machines can handle coils up to 2400 mm wide and up to 40 metric tons. If your coil does not fit these limits, you may face problems during polishing.

- You must match the machine to your coil’s width and thickness. This helps the machine run smoothly and polish well.

- The right match improves polishing speed and finish quality.

- You avoid downtime and waste when the machine fits your coil size.

- Automation and speed features work best when the coil fits the machine.

- Consistent speed and pressure give you a better surface finish.

You should also check the polishing speed and the quality of abrasives the machine uses. Faster machines help you finish more coils each day. High-quality abrasives give you a better finish.

Decision Checklist

You can use a checklist to help you pick the right machine:

- What is the width and thickness of your coils?

- Does the machine support your coil size and weight?

- What is the polishing speed of the machine?

- What types of abrasives does the machine use?

- Can the machine meet your daily production needs?

- Is the machine easy to operate and maintain?

- Does the price fit your budget?

Tip: Write down your answers. This helps you compare different machines and make a smart choice.

Application Match

You need to match the machine to your production needs. If you process many wide or thick coils, pick a machine with a high capacity. If you want a mirror finish, choose a machine that supports fine polishing stages. Some machines work better for certain coil types, like 201 or 304 stainless steel. Always check if the machine can handle your specific application.

A good match means you get better results and fewer problems. Your 6k polishing machine for metal coil processing will help you reach your quality and output goals.

Operation and Maintenance

Best Practices

You can help your 6K polishing machine work well by using good habits. Always watch the polishing temperature. Too much heat can cause small cracks, bending, and rust. Pick brushes based on the abrasive type, grain size, and how you set up the brush. This helps you avoid marks and get a smooth finish. Check brush wear often so you keep quality and speed steady. Change brush speed, feed rate, pass depth, and number of passes to get the surface roughness you want. Cryogenic cooling lowers the temperature while polishing. This makes tools last longer and keeps coils safe. Abrasive brushing also removes flaws and makes the surface smoother.

Tip: Check your machine’s settings and tools often. Small changes can improve finish quality and help your machine last longer.

- Keep polishing temperature low to stop damage.

- Pick the right brushes for each job.

- Watch brush wear and change them when needed.

- Change settings to get the best results.

- Use cooling to protect tools and coils.

Routine Care

You can stop downtime by keeping your workspace neat. Put all tools and materials close to the machine so you do not waste time looking for them. Change polishing granulate often to keep the finish shiny. Check UV lamps and replace them if they stop working. Clean inside the machine to stop buildup and keep it working well. Watch digital screens for warning signs. Use machines with easy-to-reach parts to clean and fix them faster. Simple control panels with timers and auto-stop features help you avoid mistakes and save time.

Note: A clean and cared-for machine works better and lasts longer.

Troubleshooting

If you have problems, you can fix most with easy steps:

- Lift the upper lap plate straight up about 6 inches to separate stuck parts.

- Take out stuck pieces by hand, using both hands for bigger ones.

- Use grooved lapping plates to make air paths and stop sticking.

- Add enough fluid to keep the lapping compound wet; a little soap can help lower surface tension.

- Keep the work wet, especially when lapping quartz, to stop parts from sticking.

- Glue pads to lapping plates for extra strength and to protect dropped parts.

- Slide cardboard or foam-core under the upper plate when lifting to catch falling pieces.

- Watch for the “Twyman effect” in precision polishing and change your process if needed.

If you use these steps, you can fix most problems fast and keep your machine working well.

Applications

Industry Uses

The 6k polishing machine for metal coil processing is used in many fields. Stainless steel coil finishing is needed for kitchen tools, elevator doors, and building trim. These machines help make surfaces smooth and shiny. Food factories need coils that are clean and do not rust for their machines. Builders want shiny panels for walls and doors. Car companies use polished coils for car parts and trim. Electronics makers need coils without scratches for cases and covers.

Tip: You can also use polishing machines for metals like aluminum and copper. Many factories use these machines for different kinds of metal.

Case Studies

Here are some real-life examples. A kitchenware factory wanted its stainless steel pots to look better. They put in a 6k polishing machine for metal coil processing. The pots had fewer problems and looked shinier. Another company made elevator doors. They used the machine to take away deep scratches and make the doors look like mirrors. The doors passed tough quality tests. A sheet metal supplier needed to meet national rules. They set up the machine to polish coils fast. The supplier made more coils and wasted less.

|

Industry |

Application |

Result |

|

Kitchenware |

Pots and pans |

Fewer defects, shiny |

|

Elevators |

Door panels |

Mirror finish, approved |

|

Sheet Metal |

Coil supply |

Higher output, less waste |

Success Stories

There are many good stories about polishing machines. One electronics company started using automatic polishing. They had fewer returns and customers were happier. A builder used polished coils for a new hotel. Guests liked the bright walls and clean look. You can get the same results if you pick the right machine and use it well.

Note: Metal polishing equipment comes in many types. You can choose machines for coils, sheets, or small parts. Each type helps you reach your quality goals.

You have learned how a 6k polishing machine for metal coil processing can improve your stainless steel coils. You should choose the right machine for your needs. Keep your machine clean and check it often. Good operation and care help you get the best results. If you want to learn more, talk to experts or read more guides.

Tip: Always match your machine to your coil size and finish goals for better quality.

FAQ

What types of stainless steel coils can you polish with a 6K machine?

You can polish 201 and 304 stainless steel coils. These types are common in factories. The machine also works for other metals, but you should check the specs first.

How often should you replace polishing wheels and mops?

Check wheels and mops before each job. Replace them when you see wear or scratches on coils. Regular changes help you keep a high-quality finish.

Can you use a 6K polishing machine for mirror finishes?

Yes, you can achieve a 6K mirror finish. Use fine abrasives and soft cloth wheels. Adjust the settings for the best shine.

What safety gear do you need when operating the machine?

Wear safety glasses, gloves, and a dust mask. Protective clothing keeps you safe from dust and fast-moving parts. Always follow the safety manual.

How do you troubleshoot common polishing problems?

If coils stick or show marks, check brush speed and abrasive type. Keep the work area clean. Use enough fluid and inspect the machine for worn parts.