A Complete Guide to Satin Finishing for Metal Coils and Sheets

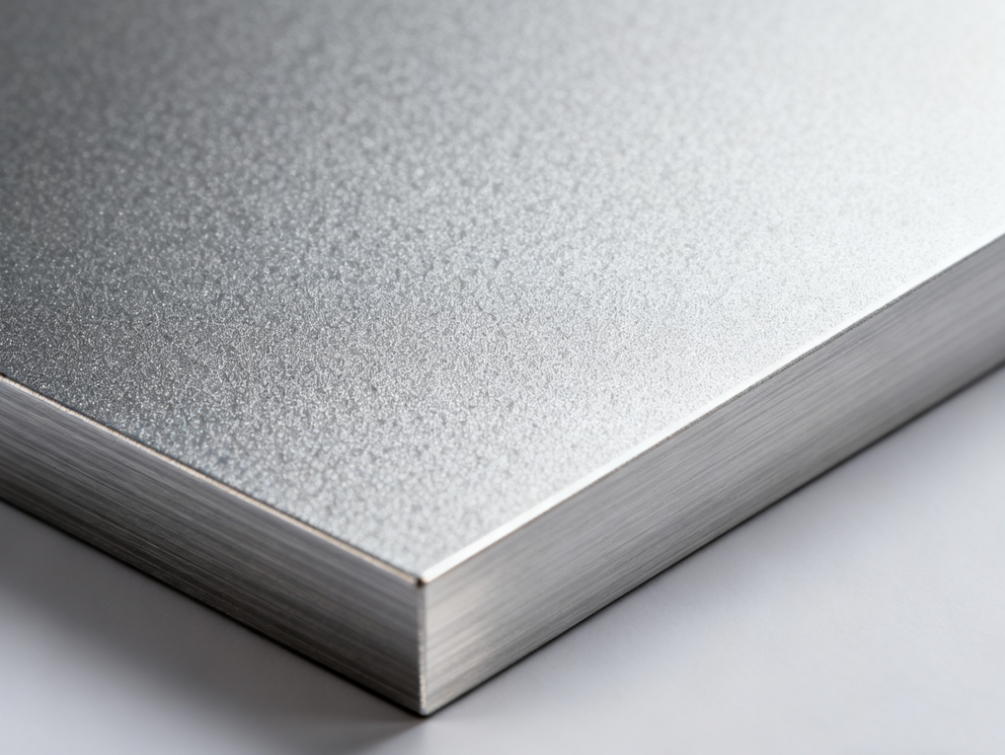

Satin finishing makes metal coils and sheets smooth and not shiny. This finish helps stop glare and hides fingerprints. It also adds a layer that protects against damage and rust. You must pick the right method for each job to get the same results every time. Using the right equipment for satin finishing of metal coils/sheets enhances their appearance and performance.

Key Takeaways

- Satin finishing gives a smooth, dull surface. It hides fingerprints and scratches. This makes it good for busy places. – Pick the right metal, like stainless steel or titanium. This helps the satin finish last long and not rust. – It is very important to prepare the surface. Always clean the metal before finishing. This helps you get the best results. – Use the right tools and methods, like polishing machines and abrasive brushes. This helps make the satin finish even. – Take care of satin-finished surfaces by cleaning them gently. This keeps them looking new and helps them last longer.

What Is Satin Finishing?

Satin finishing makes metal coils and sheets look smooth and matte. This finish does not shine like a mirror. The surface feels soft and nice when you touch it. Many industries use satin finishing to make metal look better and work better. Choosing satin finishing helps protect metal from scratches and fingerprints.

Key Features of Satin Finish

You can spot a satin finish by its special texture and look. The surface is even and has a gentle shine, but you cannot see reflections. Satin finishing uses a short grit process called a No. 4 finish. This process makes fine lines on the metal for a neat and nice look.

Tip: Satin finishes often have a plastic coating to keep the surface safe during moving and installing.

Here is a quick look at how industry standards explain satin finish:

|

Finish Type |

Description |

|

Satin |

Met with Plastic Coated |

This finish works well for stainless steel sheets and other metals that need to look good and last long.

How Satin Finishing Differs from Other Finishes?

Satin finishing is different from other metal finishes in many ways:

- Mirror finishes are very shiny and reflect a lot. Satin finishes do not show reflections and look softer.

- Brushed finishes have rough lines you can see. Satin finishes use finer tools, so the lines are hard to notice.

- Matte finishes look dull and flat. Satin finishes have a slight shine, so they look nicer.

Picking satin finishing gives you a mix of good looks and usefulness. This finish hides small marks and keeps metal looking neat and clean.

Suitable Metals for Satin Finish

Common Metals Used

There are many metals you can use for a satin finish on coils and sheets. Each metal has its own good points for your project. Stainless steel is a top pick because it does not rust and keeps looking nice. Titanium is also a good choice if you need extra strength or want to stop corrosion. Many industries use Incoloy 825 because it is strong and lasts a long time.

Here is a simple table of metals you might pick for satin finishing:

|

Metal Type |

Description |

|

Incoloy 825 |

Commonly used for satin finishing |

|

Titanium Gr 2 |

Known for its corrosion resistance |

|

Titanium Gr 5 |

Offers high strength and durability |

|

Stainless Steels |

Various grades used in the industry |

Note: Pick the metal that fits your job. Stainless steel is great for kitchens and hospitals. Titanium is better for planes or medical tools.

Factors Affecting Suitability

You should think about a few things before picking a metal for satin finishing. The hardness of the metal changes how easy it is to make the surface smooth. Softer metals can get scratched or dented more easily. Harder metals need special tools and more work to get the right finish.

If you will use the metal in wet or rough places, corrosion resistance is important. Titanium and stainless steel do not rust or stain, so they last longer. You also need to look at how thick the coil or sheet is. Thicker pieces may need different machines or take more time to finish.

It is very important to keep the surface clean. Dirt or oil can mess up the satin look. Always clean the metal before you start. If you want to hide fingerprints or scratches, satin finishing works best on metals with a fine grain.

Tip: Talk to your supplier about which metal is best for you. They can help you pick the right grade for your project and make sure you get a good satin finish.

Satin Finishing Process

Surface Preparation Steps

You must clean the metal before satin finishing. Take off all dust, grease, and oil from the coils and sheets. Use a degreaser or a gentle soap to help. Rinse the metal with water and dry it well. If you skip cleaning, you might see marks or streaks later.

Look at the metal for dents or scratches. Use rough sandpaper to smooth out bumpy spots. Sand in straight lines to keep the texture even. Switch to smoother sandpaper for a better base. Check your work as you go. A clean and smooth surface helps you get an even satin finish.

Tip: Wear gloves when you prepare the metal. This keeps fingerprints off and the metal stays clean.

Abrasive Techniques and Polishing

You need the right abrasive tools and polishing steps for a good satin finish. Start with rough abrasives to fix any problems. Use smoother abrasives to make the metal feel soft. Try polishing wheels or grinders for an even look.

Here is a table with some helpful products and ways to do satin finishing:

|

Product Name |

Description |

RPM Requirement |

|

Valgro Scotchbrite* brush finish |

Fast and emerging process for achieving various finishes including satin. |

N/A |

|

Valgro Wide Face Finishing Brush |

Designed for precision finishing of flat metal sheets, delivering uniform satin finishes. |

N/A |

|

Valgro Vibration & Non-Directional Finish Machine |

Delivers a uniform, multi-directional scratch texture known as vibration finish. |

N/A |

These tools help you make fine lines and a soft shine. Move in one direction for a classic satin look. For a mixed pattern, use vibration machines. Always check the metal after each step. If you see rough spots, use smoother abrasives and try again.

Coil Coating for Satin Finish

Coil coating is a nonstop way to get a satin finish on metal coils and sheets. The metal goes through rollers and brushes in a row. The machine puts on a thin layer that protects the metal. This layer gives the metal its satin feel and stops scratches and rust.

You can change how thick or thin the coating is. Change the speed and pressure of the rollers for different looks. Coil coating is good for big jobs and makes every piece look the same. You can use coil coating for stainless steel, titanium, and other metals.

Note: Coil coating saves time and cuts down on waste. It works best for making lots of metal pieces.

Equipment for Satin Finishing of Metal Coils/Sheets

You need good equipment for satin finishing of metal coils/sheets. The Automatic Coil to Coil Polishing Machine is important for big jobs. This machine does heavy work and helps you finish fast. It polishes both sides of the coil quickly and gives a steady satin finish.

You can also use other equipment for satin finishing of metal coils/sheets, like wide face finishing brushes and vibration finish machines. These tools help you get different textures and shines. Pick equipment for satin finishing of metal coils/sheets that fits your project and the look you want.

Take care of your equipment for satin finishing of metal coils/sheets. Clean the brushes and rollers after you use them. Look for worn parts and change them if needed. Good care keeps your equipment working well and gives you the best results.

Alert: The right equipment for satin finishing of metal coils/sheets makes your work better and saves time.

Satin Finish Properties & Benefits

Surface Texture and Appearance

If you pick a satin finish for metal coils and sheets, the surface looks smooth and fancy. The texture feels soft when you touch it. It does not shine like a mirror. You see a gentle glow that makes the metal look new and neat. This finish hides small scratches and fingerprints, so the metal stays nice even if people use it a lot.

You can tell a satin finish by its fine, even lines. These lines go in one direction or make a light pattern, based on the process you choose. Many architects and designers like satin finishes because they make kitchens, elevators, and appliances look stylish. The finish is also good for public places where you want things to look nice and stay clean.

Tip: For a matching look on big projects, always use the same equipment for satin finishing of metal coils/sheets.

Durability and Protection

A satin finish does more than make metal look good. It helps protect metal coils and sheets from daily damage. The finish acts like a shield against scratches, stains, and rust. You can use satin-finished metals in busy places, and they will last a long time.

The process makes a surface that fights rust and chemical harm. This is why satin finishes are great for kitchens, hospitals, and outdoor buildings. You do not have to clean these surfaces often because dirt and marks do not show much.

Here is a simple table with the benefits:

|

Benefit |

Description |

|

Scratch Resistance |

Hides small marks and scrapes |

|

Corrosion Protection |

Stops rust and chemical damage |

|

Easy Maintenance |

Makes cleaning quick and simple |

|

Long-Lasting Look |

Keeps metal looking fresh for years |

When you use the right equipment for satin finishing of metal coils/sheets, you make sure every piece looks good and lasts long.

Satin vs. Other Metal Finishes

Comparison with Mirror, Brushed, and Matte

You may wonder how satin finish stands out from other popular metal finishes. Satin finish, often called No. 4 finish, gives you a smooth look with a soft shine. You see fine lines that run in one direction. This finish hides small scratches and fingerprints. You often find it in kitchen appliances and building panels.

Mirror finish looks very shiny and reflects like glass. You see your face in it. This finish shows every mark and fingerprint. You need to clean it often to keep it looking perfect.

Brushed finish has visible lines that feel rougher. You notice the grain more. This finish works well if you want a bold, industrial look. It does not hide scratches as well as satin.

Matte finish looks flat and dull. You see no shine. This finish works best if you want a simple, modern style. It can show dirt and stains more than satin.

Here is a table to help you compare:

|

Finish Type |

Appearance Characteristics |

Performance Characteristics |

|

Smooth, satin look with directional grain |

Hides minor scratches and fingerprints; used in kitchens and architecture |

|

|

Mirror |

Highly reflective, glass-like |

Shows marks easily; needs frequent cleaning |

|

Brushed |

Noticeable grain, textured lines |

Industrial look; less effective at hiding scratches |

|

Matte |

Flat, no shine |

Modern style; can show dirt and stains |

Tip: Choose satin finish if you want a balance of style and easy care.

Pros and Cons

When you pick a finish, you need to weigh the good and bad points. Satin finish gives you a soft shine and hides marks. You spend less time cleaning. The finish works well in busy places.

Pros of Satin Finish:

- Hides fingerprints and small scratches

- Easy to clean and maintain

- Looks modern and professional

- Works in many settings

Cons of Satin Finish:

- Shows deep scratches more than brushed finish

- Needs special tools for repair

- May not suit every design style

You get a finish that lasts and looks good. Satin finish helps you keep metal surfaces neat with less effort.

Applications & Industries

Common Uses

You see metal coils and sheets with satin finish in many places. This finish works well for surfaces that must look clean and stay strong. You find satin finishes on kitchen appliances and elevator panels. Building facades often use satin-finished metal too. Many companies use satin-finished stainless steel for food equipment. It resists stains and is easy to clean. You also see satin finishes on car parts like trim and body panels. These parts need to look good and last long.

Satin finishes help keep surfaces free from fingerprints and scratches. People often pick this finish for doors, handrails, and wall panels in busy places. Architects like satin-finished metal for cladding and roofing. It gives buildings a modern look and protects them from weather. Hospitals and labs use this finish because it is easy to clean and keeps things hygienic.

Tip: Satin finish is a smart choice for places with lots of people. It hides marks and keeps surfaces neat.

Industry-Specific Needs

Different industries use satin-finished metal coils and sheets for special reasons. You need to match the finish to your job’s needs. The table below shows how different industries use satin-finished metals:

|

Industry |

Applications |

|

Automotive |

Cold-rolled coils help make cars lighter and stronger. They also look nice. |

|

Construction & Architecture |

Hot-rolled sheets are good for building frames, roofs, and walls because they last long. |

|

Food Processing |

Special grades like 316L and 304L are used for clean equipment and storage. |

|

Pharmaceuticals |

Non-reactive surfaces keep medical products safe during storage and processing. |

|

Oil & Gas |

Strong alloys are used for pipelines and reactors in tough places. |

|

Chemical Plants |

Durable metals help handle harsh chemicals in many uses. |

If you work with cars, you need metal that looks good and stays strong. If you build things, you want sheets that last and stop rust. If you process food, you need surfaces that clean easily and keep food safe. If you work with chemicals, you pick metals that resist damage and protect workers.

Note: Always check the grade and finish before you buy. The right satin finish helps you meet safety, style, and strength needs in your work.

Maintenance & Troubleshooting

Cleaning and Care

You need to keep satin-finished metal coils and sheets clean to protect their look and performance. Use a soft cloth or sponge with warm water for daily cleaning. For tougher spots, add a mild soap. Avoid harsh chemicals or rough pads. These can scratch the satin finish and make it look dull.

Wipe the surface in the direction of the grain. This helps keep the finish even. Dry the metal with a clean towel to stop water spots. If you see fingerprints, use a cleaner made for stainless steel or satin finishes. Spray the cleaner on the cloth, not on the metal. This keeps the finish safe.

Tip: Clean your satin-finished metal often. Regular care stops dirt from building up and keeps the surface looking new.

Here is a quick cleaning checklist:

- Use soft, non-abrasive cloths

- Clean with mild soap and water

- Wipe in the direction of the grain

- Dry with a clean towel

- Use special cleaners for fingerprints

Common Issues and Solutions

You may face some problems with satin-finished metal. Scratches, stains, and dull spots are common. You can fix most of these issues with simple steps.

|

Issue |

Solution |

|

Light Scratches |

Buff gently with a fine abrasive pad, always follow the grain direction. |

|

Stains/Spots |

Clean with a mix of water and mild soap. Rinse and dry right away. |

|

Dull Finish |

Use a satin finish restorer or a special polish for metal surfaces. |

|

Fingerprints |

Wipe with a microfiber cloth and a satin-safe cleaner. |

If you see deep scratches, you may need professional help. Do not use steel wool or strong chemicals. These can damage the finish. Always test any new cleaner on a small area first.

Alert: If you care for your satin-finished metal, you will keep it looking great and lasting longer.

Choosing the Right Satin Finish

Factors to Consider

You need to look at several factors before you pick a satin finish for your metal coils and sheets. First, think about where you will use the metal. If you need a finish for a kitchen or hospital, choose one that resists stains and is easy to clean. For outdoor projects, pick a finish that protects against rust and weather.

Check the type of metal you plan to use. Stainless steel, titanium, and special alloys each react differently to satin finishing. You should also decide how much shine you want. Some satin finishes look more matte, while others have a soft glow.

Here is a quick checklist to help you:

- What is the main use for the metal?

- Do you need high corrosion resistance?

- How much shine do you want?

- What is your budget for the project?

- What equipment for satin finishing of metal coils/sheets will you use?

Tip: Always test a small sample before you start a big job. This helps you see if the finish matches your needs.

Working with Suppliers

You should work closely with your supplier to get the best satin finish. Share your project details and ask for samples. Good suppliers will show you different finishes and help you pick the right one.

Ask your supplier about their process and the equipment for satin finishing of metal coils/sheets they use. Reliable suppliers will explain how they control quality and keep finishes consistent. You can also request technical data sheets or certificates to check the finish meets your standards.

Use this table to guide your supplier discussions:

|

Question to Ask |

Why It Matters |

|

What finishes do you offer? |

Ensures you get the right look |

|

What metals do you work with? |

Confirms compatibility with your project |

|

How do you check quality? |

Guarantees a consistent result |

|

Can I see samples? |

Lets you compare options |

Note: Building a strong relationship with your supplier helps you avoid problems and get the best results for your project.

Satin finishing makes metal coils and sheets better. It helps them last longer and stops rust. The finish also gives a modern look. You need to clean the metal first. Then you use abrasive tools to smooth it. Check the metal to make sure it looks right. Good equipment helps you get the best results. Use what you learned for your next project. You can ask an expert if you need help.

If you want to know more, read guides or talk to suppliers to learn extra details.

FAQ

What is the main benefit of satin finishing for metal coils and sheets?

You get a smooth, matte surface that hides fingerprints and scratches. Satin finishing also helps protect the metal from rust and damage. This finish is good if you want both style and strength.

Can you use satin finishing on all types of metals?

You can use satin finishing on many metals like stainless steel, titanium, and Incoloy. Some metals need special tools or extra steps to finish. Always ask your supplier which metal works best.

How do you clean satin-finished metal surfaces?

Use a soft cloth and mild soap with warm water. Wipe in the same direction as the grain. Do not use strong chemicals or rough pads. Dry the surface so you do not get water spots.

Tip: Clean often to keep the satin finish looking new.

Does satin finishing affect corrosion resistance?

Satin finishing adds a layer that helps stop rust. It works well in wet or tough places. Pick metals like stainless steel or titanium for the best results.

What equipment do you need for satin finishing?

You need polishing machines, abrasive brushes, and sometimes coil coating systems. The right equipment helps you get a smooth satin finish. Take care of your tools so they work well every time.

|

Equipment Type |

Use Case |

|

Polishing Machine |

Smooth large surfaces |

|

Abrasive Brush |

Create fine texture |

|

Coil Coating System |

Apply protective layer |