A Simple Guide to Copper Coil Slitting Machines and Their Operation

A Copper coil Slitting machine lets you cut big copper coils into thin, exact strips. This job makes smooth edges and the right widths. You need these strips for parts in electronics and cars. Smooth strips help machines stay safe and make devices work well. More people want these machines all over the world.

|

Year |

Market Size (USD) |

Projected Growth |

CAGR (%) |

|

2024 |

– |

– |

|

|

2033 |

800 Million |

– |

6.2 |

Key Takeaways

- Copper coil slitting machines slice big copper coils into exact strips. These strips are important for electronics and cars.

- You can change the machine settings for different strip sizes. This helps with many kinds of projects.

- It is important to keep the edges of copper strips smooth. Smooth edges stop problems in electronics and car parts.

- You need to take care of slitter knives often. Sharp knives make better cuts and less waste.

- Feeding copper coils without stopping makes work faster. It cuts down on waiting and helps make more strips.

Copper Coil Slitting Machine Overview

What It Is

A Copper coil Slitting machine changes big copper coils into small strips. These strips have smooth edges and exact widths. Many companies use these strips in electronics and cars. The machine is special because it works well with copper’s strength and flexibility. Other machines for metal may not do as good a job with copper. This machine is made just for copper.

Tip: You can change the machine settings to cut strips in different widths. This helps you make strips for many kinds of projects.

Here is a table that shows what a Copper coil Slitting machine does:

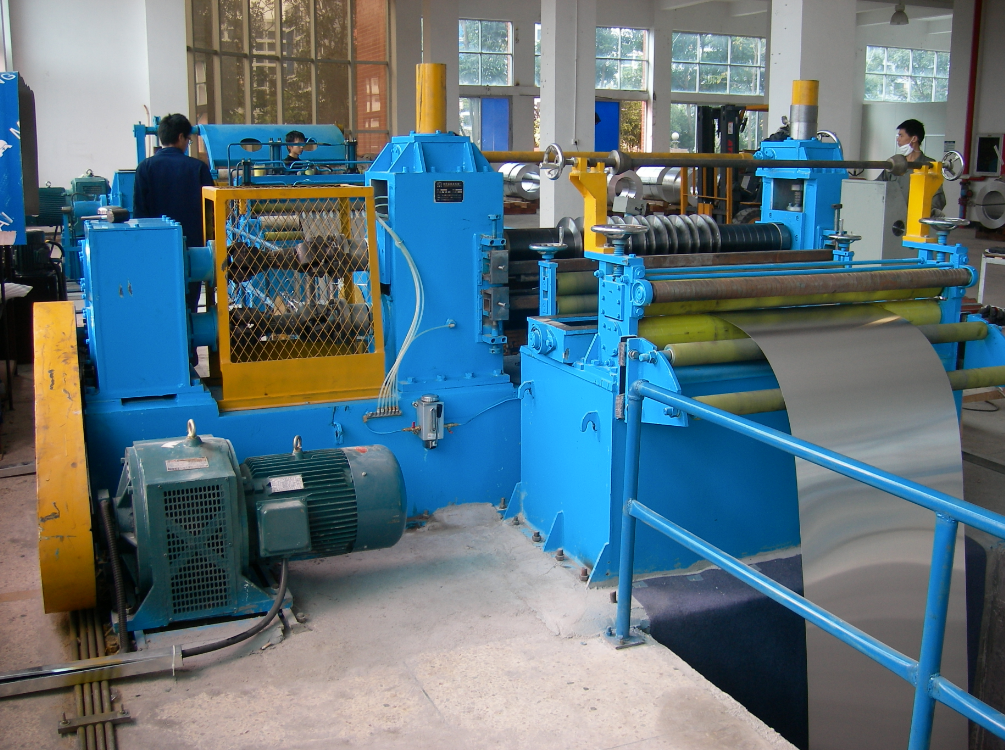

There are different kinds of Copper coil Slitting machines. Some use blades that stay in one place to cut the rolls. Others cut and then roll the strips onto new cores. Each kind helps you finish your work fast and with good results.

How It Works

First, you put a big copper coil on the machine. The machine unwinds the coil and makes it straight with rollers. Sharp round blades cut the coil into thin strips. You can set the blades to get the width you want. After cutting, the machine rolls each strip onto its own reel. Now you have neat rolls ready to use.

Here’s a simple list of what you do:

- Put the copper coil on the table.

- Unwind and straighten the coil with rollers.

- Cut the coil into strips with spinning blades.

- Move the blades to pick the strip width.

- Roll up the strips onto new reels.

A Copper coil Slitting machine works fast and keeps strips smooth. Sensors watch the strips to make sure they are good quality. You can use this machine for copper and other metals. It works best with copper because it is made for it.

Key Components

When you look at a Copper coil Slitting machine, you see many parts. Each part helps make smooth copper strips. Every part has its own job.

Uncoiler

The uncoiler is the first part. You put the heavy copper coil on it. The uncoiler does three things. It holds the coil steady. It unwinds the copper slowly. It guides the copper into the machine. This keeps the coil safe and stops tangles.

Slitter Knives

Slitter knives do the cutting. These blades are round and sharp. They slice the copper into strips. Slitter knives make sure strips are the same size. They help give each strip smooth edges.

Smooth edges matter. They keep copper safe for electronics and other things.

Slitter knives come in different materials. Here is a table with some choices:

Recoiler

After cutting, you need to collect the strips. The recoiler does this job. It rolls up the thin copper strips. The new coils are small and neat. These coils are easy to move and store. The recoiler uses a mandrel to handle narrow strips.

Other Parts

A Copper coil Slitting machine has more devices. These help the machine work well. Some are listed here:

All the parts work together. They help you get good copper strips for many uses.

Slitting Process Steps

Feeding the Coil

You start the slitting process by loading a large copper coil onto the uncoiler. The uncoiler holds the coil steady and makes sure it is ready for the next step. You position the coil securely so it does not move or slip. This step helps you avoid tangles and keeps the copper safe.

Tip: Always check that the coil sits straight on the uncoiler. This helps you get smooth strips later.

Here are the main actions you take during feeding:

- Place the copper coil on the uncoiler.

- Lock the coil in place.

- Guide the copper into the machine.

You need to make sure the coil feeds smoothly. If you rush this step, you might get uneven strips or damage the copper.

Cutting Action

The cutting action is the heart of the process. You use the Copper coil Slitting machine to slice the copper into thin strips. Rotary knives spin and cut the copper as it moves through the machine. You set the knives to the width you want for each strip.

To get clean, burr-free edges, you need to pay attention to several things:

- Machine calibration keeps everything lined up and reduces mistakes.

- Blade selection matters. High-quality blades, like carbide-tipped or ceramic, help you avoid rough edges.

- Speed control lets you adjust how fast the copper moves. Thicker copper needs slower speeds for better cuts.

- Continuous monitoring helps you spot problems right away. Sensors watch the strips and let you make quick changes.

Note: Clean edges are important for electronics and automotive parts. Burrs can cause problems in finished products.

Here is a table showing what helps you get precise cuts:

Rewinding Strips

After you finish cutting, you need to collect the strips. The recoiler takes each thin strip and winds it into a new coil. You want the strips to be tight and even. This makes them easy to handle and keeps the quality high.

The recoiler uses hydraulic systems to control tension. You avoid loose coils and keep everything neat. When you finish, you have small coils of copper strips ready for the next step or for shipping.

Tip: Organize the finished coils so you can find them quickly when you need them for production or delivery.

You inspect each coil to make sure it meets your standards. This step helps you catch any problems before the strips leave your shop.

Quality and Efficiency

Edge Quality

You need to pay close attention to edge quality when you use a Copper coil Slitting machine. Smooth, clean edges help you avoid problems in later steps. Good edge quality keeps your copper strips safe for use in electronics and cars. If you see rough or jagged edges, you might face trouble with fitting parts or even safety risks.

To get the best results, you should focus on a few key methods. The table below shows some ways you can keep edges smooth and precise:

Tip: Clean edges make your copper strips safer and easier to use in any project.

Common Issues

You may run into some common problems during copper coil slitting. These issues can affect the quality of your strips and slow down your work. Here are some of the most frequent problems:

- Surface defects like rust, stains, dents, mill marks, scratches, and laminations.

- Specification issues with width, thickness, or tolerance.

- Burrs or rough edges on the strips.

- Strips that do not match the size you need.

If you spot these problems early, you can fix them before they cause bigger trouble. Always check your strips after slitting.

Production Benefits

When you use continuous feeding in your process, you boost your efficiency. The machine keeps moving the copper coil through without stopping. This means you can make more strips in less time. You also lower the risk of mistakes because the process stays steady.

Continuous feeding helps you:

- Reduce downtime between coils.

- Keep strip quality the same from start to finish.

- Save time and money on each job.

Note: A well-run slitting process gives you more good strips and less waste. You get better results for every project.

Applications

Electronics

Copper strips are used in lots of electronics. They help move electricity inside circuit boards and switches. Phones and computers need copper strips to send power and signals fast. Smooth edges and the right size from a Copper coil Slitting machine help each strip fit well. This keeps devices safe and helps them last longer. You also see copper strips in batteries, chargers, and smart home wires.

Automotive

Copper strips are important in cars and trucks. They are found in wiring harnesses and battery parts. These strips help the car’s electrical system work well. Here are some ways copper strips help vehicles:

- Copper strips carry electricity well, so headlights and sensors lose less power.

- They do not rust easily, so car wires last longer in bad weather.

- Copper strips bend easily, so they are good for connectors.

- Electric and hybrid cars use copper strips to move battery power.

Cars need copper strips that follow strict rules. Here is a table with some common details:

Other Uses

Copper strips are used in many other places. Builders use them for roofs and trim. Factories use copper strips in plumbing and hardware. Copper strips are also important for renewable energy. You see them in solar panels and wind turbines. These strips help move electricity in solar panel wires and wind turbine generators.

- More money spent on solar panels and wind turbines means more copper strips are needed.

- Copper strips help solar panels and wind turbines work better by moving electricity well.

Note: As new technology grows, copper strips will be used even more in different industries.

You now know how a Copper coil Slitting machine changes big copper coils into exact strips. These strips are used in many industries. The uncoiler, slitter, and recoiler all work together. They help move the copper and make clean cuts. Cameras and sensors check for mistakes and keep strips the right size.

Think about how this process helps factories today. If you have questions or ideas, write a comment below!

FAQ

What safety steps should you follow when using a copper coil slitting machine?

You should always wear gloves and safety glasses. Check the machine before you start. Keep your hands away from moving blades. Follow all safety signs. If you see a problem, stop the machine right away.

How often should you maintain the slitter knives?

You should check and clean the slitter knives after each use. Sharpen or replace them if you see dull edges. Regular maintenance helps you get smooth cuts and keeps the machine running well.

Can you use a copper coil slitting machine for other metals?

Yes, you can use the machine for other soft metals like aluminum or brass. You may need to adjust the blade settings. Always check the machine guide before you try a new material.

Why do you need smooth edges on copper strips?

Smooth edges help you avoid cuts and damage. They also make the strips safer for electronics and car parts. Rough edges can cause short circuits or break wires.