Essential Maintenance Steps for Metal Coil Slitting Machines

Regular maintenance helps your metal coil slitting machine work well and stay safe. You keep workers safe and get good results when you look after your equipment. Simple things, like cleaning and checking parts, stop bigger problems from happening. Act early before problems start. Doing this saves time, helps the machine last longer, and stops expensive breaks. Your care really matters every day.

Key Takeaways

- It is important to clean your metal coil slitting machine often. Clean it every day to stop dirt from building up. This helps the machine work well.

- Lubrication is very important for the machine to last long. Put oil on moving parts every 3 to 4 hours. This helps stop parts from rubbing and wearing out.

- Check the blades often. Look for chips and dull spots every day. This keeps the cuts good and the machine safe.

- Inspect electrical parts often. Check for loose wires and test safety tools. This helps stop accidents from happening.

- Keep a good maintenance log. Write down all the work you do on the machine. This helps you see problems and stop them in the future.

Cleaning Procedures

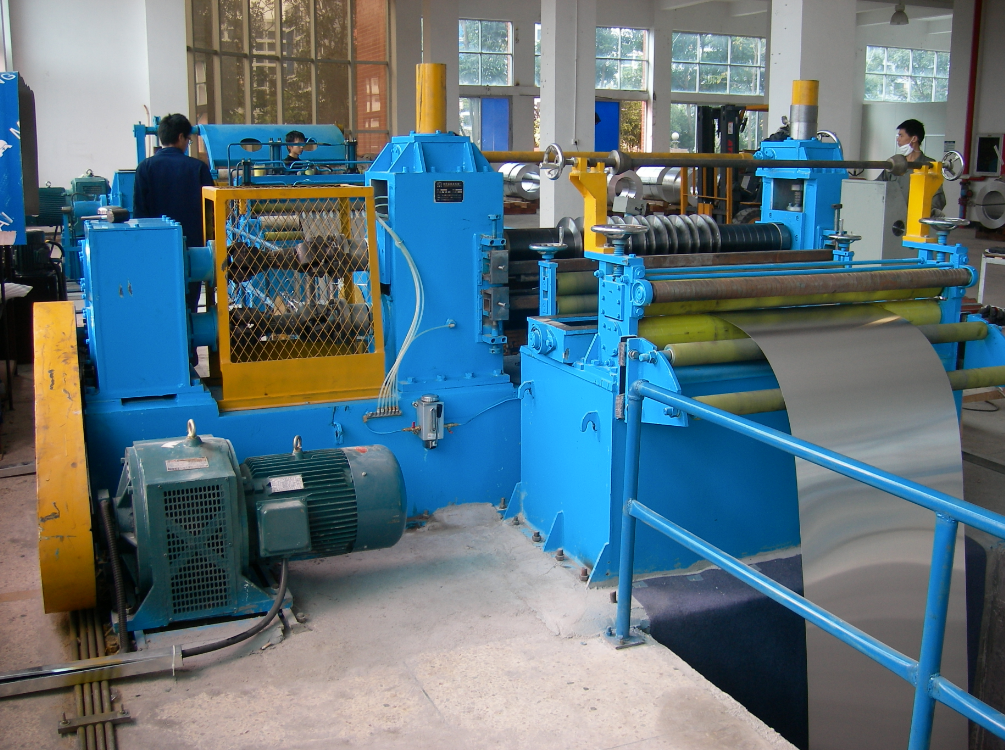

Metal Coil Slitting Machine Cleaning

You need to clean your metal coil slitting machine every day. Dust and dirt can build up fast. If you let this happen, your machine may not cut metal as well. Clean machines help you avoid flaws in the cutting process.

- Wipe down all surfaces with a clean cloth.

- Check for any oil spills or sticky spots.

- Make sure to look at hard-to-reach areas.

A daily cleaning routine keeps your machine in top shape. You should also include daily inspections in your maintenance schedule. These inspections help you spot problems early.

Removing Chips and Debris

Metal chips and debris can cause damage if you leave them on the machine. Always remove chips after each shift. Use a brush or compressed air to clean motors and drives.

Tip: Use a soft brush for delicate parts. Compressed air works well for tight spaces.

If you keep the machine free from debris, you lower the risk of jams and wear. Clean rollers and guides to prevent scratches on the metal coil.

Oil Management

Oil leaks can make the shop floor slippery and unsafe. You need a good oil management system to keep things safe.

- Check oil levels every day.

- Wipe up spills right away.

- Use drip trays under the metal coil slitting machine.

A clean and dry floor helps prevent accidents. Proper oil management also protects the machine from rust and other damage.

Lubrication

Lubrication Points

It is important to know where to put lubricant. Focus on the moving parts of the machine. These parts are blade shafts, bearings, gears, and guide rollers. You should look in the manufacturer’s manual for a full list.

- Blade shafts

- Bearings

- Gears

- Guide rollers

Lubricating these parts helps the machine work well. It also lowers the chance of breakdowns.

Lubricant Selection

Picking the right lubricant is important. Each kind works best in certain situations. Here are the main types you might use:

- Mineral Oils: Good for normal temperatures. They come from crude oil and work for most daily jobs.

- Synthetic Oils: Best for high speeds or tough conditions. These oils last longer and protect better when stressed.

- Greases: Stay in place and work well for parts that need steady lubrication.

Tip: Always use the manufacturer’s advice when choosing a lubricant. Using the wrong type can hurt the machine or make it work badly.

Lubrication Schedule

Lubricating your metal coil slitting machine helps it last longer. Oiling parts lowers friction on the blade’s edge. This keeps heat and wear down. It also stops thermal expansion, which can make blades less accurate.

You should add lubricant every 3-4 hours if the machine runs all day. Make it a habit to check oil levels and add more when needed.

- Set reminders to lubricate often.

- Keep a chart to track when you last oiled each part.

Regular lubrication keeps your machine safe and working well. It also saves money on repairs.

Blade Maintenance

Blade Inspection

Check the blades on your metal coil slitting machine often. Look at them every day to find problems early. Watch for chips, cracks, or dull spots on the blade. Wipe the blade with a clean cloth after each shift. Use a flashlight to see cracks or damage on the blade.

Here is a table that lists why blades wear out:

Note: Always look closely at blade edges for chips when you check.

Blade Sharpening and Replacement

Sharpen and replace blades at the right time to keep the machine working well. Dull blades cut badly and can hurt the metal. Test if the blade is sharp every week with real material. Measure blade thickness every month with a caliper or micrometer. If you see chips or cracks, change the blade right away. If the blade wears unevenly, replace it too.

- The type of material changes how fast blades wear out.

- Thicker material makes blades wear out faster.

- Dull blades should be replaced.

- Blades with chips or cracks must be changed.

- If the blade wears unevenly, get a new one.

Blade Alignment

Make sure the upper and lower blades line up right. Good alignment stops vibration and gives better cuts. This helps blades last longer and keeps the machine safe. Industry rules say that good alignment is important for blade life and less wear.

Tip: Check blade alignment after you change a blade. Use alignment tools to make sure blades match up.

Following these blade maintenance steps helps your metal coil slitting machine work better and last longer.

Electrical Checks

Wiring Inspection

You should check the wiring on your metal coil slitting machine often. Loose wires can make short circuits or even cause electric shock. Look for wires that are frayed or have no cover. Also, check for spots that look too hot. If you see any damage, fix it right away.

Blown fuses and tripped circuit breakers happen a lot with these machines. These problems keep the system safe from too much electricity, but they also stop your work. Use a multimeter to check for short circuits. Make sure all the connections are tight.

Tip: Always turn off the power before you look at or touch any wires.

Safety Devices

Safety devices help keep you and your team safe when using the machine. Emergency stop buttons and safety switches must work every time. Test these devices before each shift.

- Press the emergency stop button to see if the machine stops.

- Check safety switches to make sure they work right.

- Replace any safety parts that are broken or worn out.

If safety devices do not work, accidents can happen fast. Checking them often helps stop injuries and keeps your shop safe.

Control Panel Monitoring

The control panel runs the whole machine. If the control panel is not working, the machine can stop or make mistakes. You should look for warning lights, error codes, or strange noises.

Motors might not start if the control panel has problems. Power that is not steady or bad parts can cause these issues.

Check the control panel every day. If you find a problem, fix it before you start work. This helps your metal coil slitting machine stay safe and work well.

Mechanical Adjustments

Tension Settings

You need to check the tension settings on your metal coil slitting machine before every shift. Tension keeps the metal strip flat and smooth as it moves through the machine. If you set the tension too high or too low, you can cause problems like wrinkles, scratches, or wavy edges. These defects lower the quality of your finished coils.

- Consistent tension helps you avoid coil breaks and edge burrs.

- The right tension keeps the strip flat and uniform.

- Good tension control reduces waste and keeps production costs down.

- Proper tension also protects you and your team by lowering the risk of sudden coil breaks.

Tip: Always adjust tension slowly and watch the strip as it moves. If you see any signs of stretching or bending, stop and reset the tension.

Bearings and Gears

Bearings and gears help your machine run smoothly. You should listen for strange noises or feel for extra vibration. These signs often mean a bearing or gear needs attention. Worn bearings can cause the machine to shake or make loud sounds. Damaged gears may slip or grind.

- Check bearings and gears for wear every week.

- Look for signs of rust, cracks, or missing teeth.

- Lubricate moving parts as recommended by the manufacturer.

If you find a problem, replace the part right away. This keeps your machine safe and helps it last longer.

Feed and Slitting Mechanisms

Feed and slitting mechanisms guide the metal strip and cut it to size. You should inspect these parts every two weeks for wear and alignment. Regular checks help you spot problems early and keep your cuts straight.

- Clean and inspect the feed rollers and slitting knives.

- Make sure all parts line up correctly.

- Follow the manufacturer’s maintenance schedule for best results.

Keeping these mechanisms in good shape helps you avoid jams and keeps your production running smoothly.

Operator Training

Training Sessions

You should go to training often. Training helps you use the metal coil slitting machine safely. You learn about new features and updates. Trainers teach you how to set up the machine. They show you how to change settings. You learn how to handle materials. You get to practice with real equipment.

- Ask questions if you do not understand something.

- Watch trainers show you how things work.

- Practice each step until you feel sure.

Tip: Write notes during training. You can look at them later if you forget.

Safe Practices

You need to follow safe rules every time you use the machine. Wear safety gear like gloves, goggles, and ear protection. Keep your work area clean and neat. Always check that guards and safety devices are ready before you start.

- Never put your hands in the machine when it is running.

- Use tools to take out metal scraps, not your hands.

- Stay focused and do not get distracted.

Here is a simple safety checklist:

Issue Reporting

You should tell someone if the machine has a problem. If you hear odd sounds or see warning lights, tell your supervisor. Write down what you see and when it happens. Reporting problems quickly helps fix small issues before they get worse.

- Use a notebook or computer form to write down problems.

- Explain the problem so others understand.

- Check back to make sure repairs are done.

Reporting problems keeps everyone safe and helps the metal coil slitting machine work well.

Maintenance Schedule

Inspection Intervals

Set clear times to check your metal coil slitting machine. Regular checks help you find problems early. Daily checks are for cleaning and safety devices. Weekly checks look at blade wear, bearings, and gears. Monthly checks cover control panels and alignment.

A simple table helps you remember when to check each part:

Checking your machine on a schedule keeps it safe. It also helps stop surprise breakdowns.

Checklists

Checklists help you stay neat and careful during maintenance. Using a checklist means you do not skip steps. You can plan and finish each job with care.

- Checklists make maintenance regular and stop surprise breakdowns.

- You find problems early, so your machine works well.

- A checklist helps you plan and finish every job.

- Without a checklist, you may skip steps and get confused.

- Good checklists help you follow rules and keep your machine working.

- You can change your checklist as your shop grows.

Use a checklist every time you check or fix your machine. This habit saves you time and money.

Assigning Tasks

Give maintenance jobs to the right people. This makes sure everyone knows what to do and when.

- Put maintenance jobs on a calendar. This helps you stop equipment failures.

- Make sure everyone does jobs the same way.

- Train your team often to build skills and safety.

- Watch how the machine works to find problems early.

- Use mobile apps for updates and tracking jobs.

- Make sure everyone puts in data the right way. Automated tools help with this.

- Look at maintenance data to find ways to do better.

You can pick a maintenance planner. This person organizes jobs and checks that everyone finishes their work.

Giving jobs and tracking progress helps your team stay on track. It also keeps your machine working well.

Maintenance Log

Activity Records

It is important to keep records of every maintenance job. Write down what you do right after you finish. Good records help you see patterns and catch small problems early.

- Write the date and time for each job.

- Write the name of the person who did the work.

- List the parts you checked, cleaned, or replaced.

- Note any strange sounds, smells, or machine actions.

- Keep manuals and parts lists together for easy use.

When you keep good records, planning future maintenance is easier. Your team can work together and not miss steps.

Repairs Tracking

Tracking repairs helps you know which parts break a lot. This helps you plan better and save money.

- Write down every repair, big or small.

- Include the date, time, and what went wrong.

- List the parts you fixed or replaced.

- Write who did the repair and how long it took.

- Keep all repair records in one place.

Good repair tracking helps you see problems that happen again. You can plan to fix things before they get worse. This keeps your machine working and stops long breaks.

Keeping good records of maintenance and repairs helps you find problems that happen again and plan fixes. This also helps your machine last longer and saves money.

Log Review

You should look at your maintenance log often. Checking your log helps you see patterns and make your plan better. When you look back, you can see which problems happen a lot. This helps you fix the main cause and stop future breakdowns.

When you check your log, you make your plan stronger. Your machine works better and lasts longer.

- Check logs every week or month, depending on how much you use the machine.

- Look for problems or parts that break a lot.

- Change your maintenance plan based on what you find.

A good maintenance log helps you get great results, stop long breaks, and keep your machine working well.

If you take care of your metal coil slitting machine often, it works better. Checking the machine regularly helps you stop sudden problems. This also keeps your team safe. Experts say that doing maintenance before things break means fewer stops and a longer life for your machine.

Taking care of your machine early saves money. It also makes your machine more reliable. You will notice less cost and more time when your machine is running.

If you follow these steps, your machine will last longer. It will also work better every day.

FAQ

How often should you clean your metal coil slitting machine?

You should clean your machine every day. Daily cleaning helps prevent dirt and metal chips from causing damage. Regular cleaning keeps your machine safe and working well.

What lubricant works best for slitting machines?

You should use the lubricant recommended by your machine’s manufacturer. Mineral oils work for most jobs. Synthetic oils protect better in tough conditions. Always check your manual before choosing a lubricant.

Why do you need to check blade alignment?

Blade alignment helps you get straight cuts and keeps blades from wearing out too fast. You should check alignment after changing blades or if you see uneven cuts.

What safety gear should you wear when operating the machine?

You should wear gloves, safety goggles, and ear protection. Safety gear protects you from sharp metal, loud noise, and flying debris. Always check your gear before starting work.

How do you track maintenance and repairs?

You should use a maintenance log. Write down each job, the date, and who did it. Tracking helps you spot problems early and plan future repairs.