Everything You Need to Know About Metal Coil Slitting and Cutting

Metal coil slitting and cutting change big metal coils into exact strips or sheets. These strips or sheets are used for making things. These processes are very important in car and building industries. The coil slitter market around the world may be worth more than USD 1.9 billion by 2029. This growth is because of more machines and higher need in factories. Many companies use metal coil processing to work faster and get the right materials.

|

Industry |

Usage Percentage |

Key Application Areas |

|

Metal Industry |

Steel, aluminum, automotive, construction |

|

|

Machinery Industry |

39% of CNC slitting applications |

Agricultural, industrial machinery |

|

Fabrication Units |

Over 61% adopted automation |

Metalworking operations |

Key Takeaways

- Metal coil slitting cuts big metal coils into exact strips. These strips are used in cars, buildings, and appliances. This process helps factories work faster and use materials better.

- Modern slitting machines are very accurate and work quickly. They make less waste than old cutting methods. This saves money and materials.

- The steps for metal coil processing are loading, straightening, slitting, recoiling, and packaging. Each step needs careful setup and quality checks.

- Advanced machines like hydraulic uncoilers, automated slitters, and tension-controlled recoilers are used. They help keep the metal flat, smooth, and ready to use.

- Metal coil slitting helps industries like automotive, construction, appliances, and packaging. It gives custom sizes and better product quality.

What Is Metal Coil Slitting?

Slitting Definition

Metal coil slitting changes big coils of metal into thin strips. Workers put a master coil into a slitting machine. Rotary knives on the machine cut the coil into many strips called mults. Each strip must be a certain width and have smooth edges. The process uses special machines like an uncoiler, slitter, and recoiler. These machines unwind, cut, and rewind the metal into new coils. This method helps industries that need exact metal strips for making products.

Key Features

Metal coil slitting is different from other ways to process metal coils because it is very exact and fast. Workers use advanced machines to get perfect results.

- The process begins by unwinding a master coil of steel or other metals.

- Rotary knives on the slitter head cut the coil into thin strips.

- Special machines like decoilers, slitters, and recoilers make sure the strips are the right size.

- Workers check each strip for the right width and smooth edges.

- The recoiling step keeps the strips flat and free from bends, which keeps them high quality.

- Careful machine settings help make less scrap and save money.

- This method makes slit steel coils for cars, buildings, and home appliances.

Slitting vs. Cutting

Metal coil slitting and regular cutting both shape metal, but they are not the same. They are different in how exact they are, how fast they work, and how much waste they make. The table below shows these differences:

Modern metal coil slitting uses special tension control and servo-driven systems. These features keep the metal from getting too stressed and stop mistakes. Automatic threading and built-in systems help cut down on waste and make changeovers faster. Real-time quality checks, like laser measuring and edge checks, let workers fix problems right away. These upgrades make cutting more exact, faster, and use more of the metal. Regular cutting does not have as much accuracy or automation. Because of this, slitting technology helps companies work better and spend less money.

Metal Coil Processing Steps

Metal coil processing turns raw metal into strips or sheets. These strips or sheets are ready for making things. Each step uses special machines. Workers must pay close attention to details. The next parts explain the main steps, from loading the coil to packing it.

Loading and Uncoiling

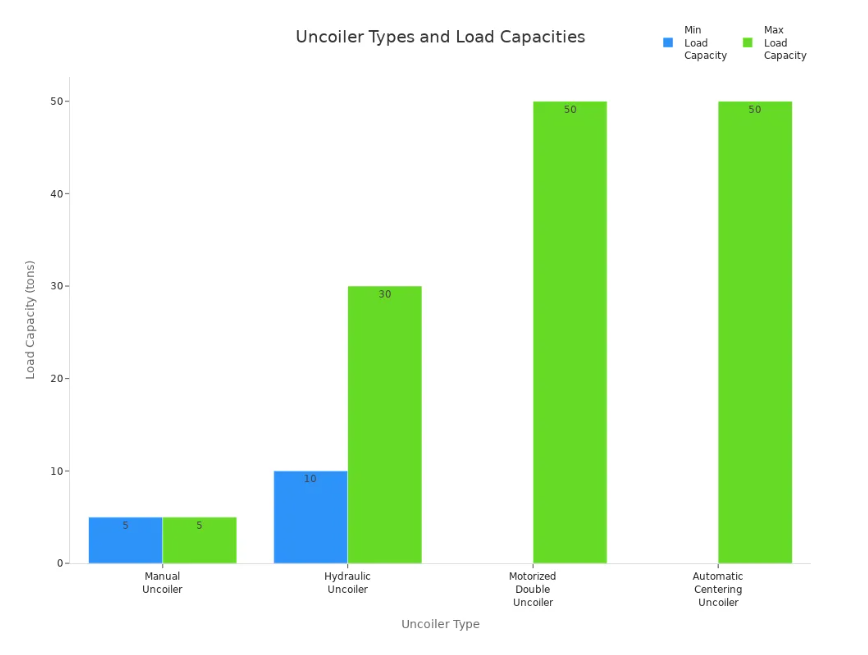

Workers start by putting big coils on an uncoiler. The uncoiler holds the coil and feeds it into the line. There are three main kinds of uncoilers: cone, single mandrel, and dual mandrel. Single mandrel uncoilers are used most in slitting and cut-to-length lines. These machines grip the coil with an expanding mandrel. They use a hold-down roll to keep the coil steady. A sliding base helps line up the coil. Hydraulic and motorized double uncoilers can lift heavier coils. They also let workers change coils faster.

Tip: Lining up the coil right at the start stops jams and mistakes later.

Straightening

After uncoiling, the metal goes through a straightener. This machine takes out bends and makes the strip flat. Straightening is very important for good slitting and cutting. Workers set the rollers for the metal’s thickness and hardness. Even small mistakes can cause bad edges or other problems. Checks at this step help find issues early.

Slitting Operation

The main part of metal coil processing is slitting. Rotary blades, called slitter knives, cut the wide coil into thin strips. Workers set the knives to the right widths for each job. Tension control keeps the metal steady and stops stretching or wrinkles. New slitting lines use sensors and machines to watch blade spots and strip width all the time. This step needs careful setup and lots of checks to stay exact.

Note: Setting up the knives and tension just right makes less waste and saves more metal.

Recoiling and Packaging

After slitting, the strips go to the recoiler. The recoiler rolls each strip into a new coil. This keeps the edges smooth and the strip flat. Workers watch the coil’s tension and line-up to stop loose wraps or uneven coils. After recoiling, workers label and pack the coils for customers. Packing can use wraps, straps, or special pallets. The last check makes sure each coil is good before shipping.

Typical Metal Coil Processing Sequence

- Hot Rolling: Steel slabs are heated and rolled to make the first coil.

- Pickling: The coil gets a chemical bath to clean it.

- Cold Rolling: The coil is rolled cold for better strength and finish.

- Precision Rerolling: More rolling makes the size more exact.

- Annealing: Heating makes the metal softer again.

- Slitting: The coil is cut into thin strips.

- Final Finishing and Packaging: Coils get surface treatments and are packed for delivery.

Checking quality at every step makes sure the results are always good and customers are happy.

Equipment Overview

Uncoilers

Modern uncoilers are very important in metal coil processing. Hydraulic decoiler machines use strong hydraulic systems to move heavy coils of steel, aluminum, or copper. These systems give a lot of power and let workers control the coils exactly. This helps unwind big coils safely. The hydraulic fluid makes the movement smooth and steady. This keeps the metal safe from harm. Uncoilers help workers turn big coils into flat sheets for the next step. They work well in busy places like car and building factories.

- Hydraulic systems are small but very strong.

- Smooth unwinding keeps the metal in good shape.

- Good machines mean workers do not have to move coils by hand as much.

Tip: If the uncoiler feeds the metal well, the whole process works better.

Slitting Machines

Slitting machines have gotten much better in the last ten years. Many now have fast loading systems that do not need a shaft and can be controlled from far away. This saves time and puts the rolls in the right spot. Some machines can set up to 20 knives by themselves in less than two minutes. This means less waiting and more exact cuts. Closed loop tension control uses special sensors to keep the right pull on the metal. This helps make good rolls every time. Fast roll unloading lets workers change rolls quickly and do less by hand. These new features make slitting machines more exact and faster.

- Automation means less work for people and more finished metal.

- Tension control keeps the product the same every time.

Straighteners

Straighteners take out bends and waves from metal strips before slitting. They use rollers set for the metal’s thickness and hardness. Good straightening is needed for the process to go well. If the strip is not flat, it can cut badly or jam the machine. Workers set the rollers for each coil so the strip goes into the slitting machine the right way.

Recoilers

Recoilers roll up the slit strips into new coils after checking them. They can work at speeds from 20 to 200 meters each minute. They handle coil widths from 150 mm to over 2500 mm. The recoiler keeps the right pull and lines up the metal during fast rewinding. This helps check quality and gives customers what they want. By working with other machines, the recoiler helps the line run without stopping and keeps the product good.

Note: The recoiler must keep the right pull to make coils the right size.

Ancillary Tools

Some extra tools help make metal coil processing safe and easy. Sheet metal decoilers help uncoil, straighten, and feed metal into slitting machines. This makes moving metal easier and helps workers do more. These tools also mean workers do not have to move heavy metal by hand as much, so it is safer. Training for workers is also very important. Trained workers know how to use the machines, follow safety rules, and do their jobs well. This means less waiting and fewer accidents.

- Extra tools help the work go faster and keep people safe.

- Training helps workers use the machines the right way.

Benefits

Efficiency

Metal coil slitting lines help factories work faster. Automated feeding and tension control keep things running well. These features cut down on waiting and speed up work. Operators can set up new jobs fast. This means less waiting and more products made. Many machines let workers change knives quickly. They can also change strip widths without stopping. This helps companies fill different orders without delays. Because of this, factories can send products on time and meet big orders.

Precision

Modern slitting machines are very exact. Operators use special tools to check every strip. They follow strict rules to make sure strips are right. The table below shows how they check for accuracy:

These checks make sure strips have smooth, straight edges. Good quality helps factories avoid mistakes and keep customers happy.

Material Utilization

Metal coil slitting helps companies use more metal and waste less. Exact cutting keeps edges neat and sizes correct. Machines can change strip sizes without stopping the line. The table below shows how things get better:

These changes save money and use more of the metal.

Customization

Slitting lines let workers pick thickness, width, and coil size for each job. The process works for thicknesses from 0.010″ to 0.500″ and widths from 0.375″ to 84″. Tight rules, like +/- 0.005″, make sure strips fit their job. Car, building, and appliance makers use these choices. Custom options help them meet special needs, make better products, and work faster.

Tip: Custom slitting helps companies react fast to new orders and customer needs.

Applications

Automotive

Metal coil slitting is very important for making cars. Car makers use slit coils to make car bodies and strong parts. The process gives strips with the right width and smooth sides. This helps car makers follow strict rules for quality. Fast slitting machines help make lots of cars quickly. Many car parts need to be light and strong. Companies pick stainless steel or aluminum slit coils for better gas mileage and safety. These metals also help meet green rules. Stamping plants use slit coils to make many car parts.

Slitting lines make strips that help build safer, better cars.

Construction

Builders need metal coil slitting for many building jobs. The process cuts big coils into thin strips for each project. Steel and aluminum slit coils are strong and easy to use. Builders use these strips for stamping, deep drawing, roll forming, and coining. Some building products made from slit coils are:

- Roofing panels and trims

- Window and door flashings

- Flat sheets for repairs and flashing

Slit coils come in many colors and looks, which makes roofs and flashings look nice. Metal roofing from slit coils does not rust or burn easily. These products also help save energy and can be recycled.

Appliances

People who make appliances use slit coils for parts in fridges, ovens, washers, and dryers. The process lets them pick the right thickness and width for each part. Slit coils help make strong and light panels and frames. Appliance makers like the smooth sides and even sizes from slitting. These things help put products together faster and make them better. Stainless steel and coated steel slit coils are used a lot because they do not rust and look good.

Packaging

The packaging industry uses metal coil slitting to get coils ready for shipping and storage. Machines take slit coils off the line and put them on belts. Banding stations put steel straps around each coil to keep them safe. Cranes lift and stack coils on pallets for shipping. These steps mean workers do less heavy lifting and work goes faster.

Automated packaging lines help make sure slit coils get to customers safely and ready to use.

Choosing Equipment or Partner

Machine Types

Picking the right slitting machine depends on what you need. There are different types for different jobs:

· Center-Winders turn the roll from the middle. They work well for medium speeds and sizes. They can rewind rolls up to 32 inches wide. People use them for log winding and simple materials.

· Center-Surface Winders spin the roll at the middle and outside. They handle bigger and heavier rolls, up to 50 inches wide. You can change the pressure for soft or thin materials.

· Surface-Winders move the roll by its outside edge. They work with the biggest and heaviest rolls, up to 80 inches wide. They can go as fast as 6,000 feet each minute. Factories use them for wide and heavy materials.

· Differential Shaft Slitters work with many core types. They give exact and steady cuts. They are easy to fix and change.

· Razor and Score Slitters are for soft or thick stuff. Razor slitters cut things like cloth and foam. Score slitters cut thick things like cardboard.

Sheet metal slitting machines use strong motors and blades. They cut hard or thick metals. Safety and automation help workers do their jobs faster and safer.

Selection Factors

To pick the best machine, start with the metal type. Workers must check how thick and wide the metal is. The machine must fit the strip width and how close the cuts need to be. If you make a lot, you need a bigger machine. Automation, like easy controls and blade changes, helps work go faster. Good blades and easy care make better products. Pick machines that let you change blades quickly.

Tip: Always choose a machine that can handle your hardest and thickest metal.

Service Partners

A good service partner keeps things running well. Companies should pick partners who know their industry. Good partners give quick help, spare parts, and training. They should have clear plans for care and safety. Reading reviews and asking others helps find the best partner. A strong partner helps stop problems and keeps machines working.

Note: Having a trusted partner helps your company do better for a long time.

Metal coil slitting and cutting help factories work better and faster. Companies can make up to 30% more products and waste less metal with new slitting machines. Keeping machines in good shape and having trained workers makes them last longer and keeps everyone safe.

- Better accuracy means less fixing mistakes

- Even slit widths help the next steps go smoothly

- Machines that work by themselves help stop injuries

If you want to learn more, you can read Modern Metals, MetalForming Magazine, and Cutting Tool Engineering Magazine. These have new ideas and tips for people who work with metal.

FAQ

What metals can companies process with coil slitting machines?

Steel, aluminum, copper, and stainless steel are used a lot. Some factories also work with special alloys. The machine settings change for each metal’s thickness and hardness.

How do operators ensure precise strip widths?

Operators use digital controls and special measuring tools. They check the strip width with calipers and sensors. If the width changes, automated systems warn the workers.

Is metal coil slitting safe for workers?

Modern machines have safety guards and emergency stop buttons. Workers get training to stay safe. Regular checks help keep the equipment safe to use.

How often should companies maintain slitting equipment?

Experts say to check machines every day. Full maintenance should happen every few months. Taking care of machines stops breakdowns and keeps work going well.