How Automatic Metal Steel Sheet Handlers Boost Efficiency in Metal Processing?

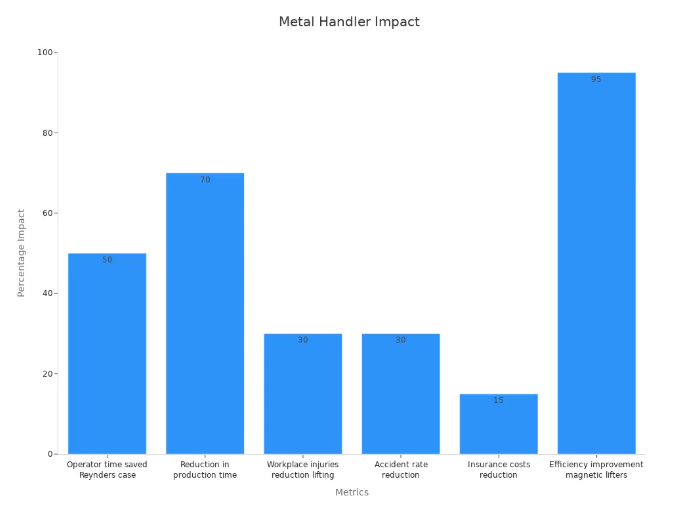

The Automatic Metal Steel Sheet Handler in metal processing revolutionizes factory operations. This automation integrates vacuum suction panel handlers and robotic systems, significantly saving time and enhancing worker safety. The chart below highlights a 50% reduction in operator time and a 30% decrease in workplace injuries.

|

Metric Description |

Statistic / Percentage |

Impact on Manual Labor and Metal Processing Industry |

|

Operator time saved (Reynders case) |

50% |

Significant reduction in manual labor time, allowing workers to focus on other tasks |

|

Reduction in production time |

70% |

Faster processing with less manual intervention |

|

Reduction in workplace injuries related to lifting |

30% |

Improved safety as machines handle heavy lifting |

|

Reduction in accident rates |

30% |

Enhanced workplace safety due to automation |

|

Reduction in insurance costs |

15% |

Cost savings from fewer accidents |

|

Efficiency improvement with magnetic lifters |

95% |

Superior handling compared to traditional manual methods |

|

Labor cost savings |

N/A |

Reduced workforce requirements thanks to automation |

The Automatic Metal Steel Sheet Handler in metal processing, equipped with vacuum suction panel handlers, enables machines to operate longer and more efficiently. Factories can increase production output while minimizing errors.

Key Takeaways

- Automatic metal steel sheet handlers help save time. They cut operator work in half. They make production up to 70% faster.

- These machines make the workplace safer. They lower injuries by 30%. Workers do not have to lift heavy things.

- Vacuum suction can make more products. There are fewer mistakes.

- Automation means less downtime and lower maintenance costs.Machines can run longer. They make more steel sheets each day.

- Factories using these handlers get better quality. They have less waste. They deliver products faster. This helps profits and makes customers happier.

What Are They?

Core Functions

Automatic metal steel sheet handlers are important in today’s metal factories. These machines move and lift heavy steel sheets with great accuracy. Factories use them to make work faster and easier for people. The handlers often work together with other machines like cutting or welding tools. This helps the whole process go smoother.

Key functions include:

- Lifting and moving steel sheets safely

- Putting sheets in place for cutting or welding

- Keeping people away from dangerous spots

- Watching where sheets go to stop mistakes

These systems help companies waste less material and time. They also help avoid doing the same work twice. Handlers can make quick changes to keep things running well. Smart controls and monitors help machines work longer without stopping. Diagnostic tools give info about the machine’s health. This helps fix problems faster and keep everything working.

Note: Automated handlers can cut rework by half. They help make less scrap and speed up production. They also make the workplace safer by keeping people out of risky areas.

Key Technologies

Modern steel sheet handlers use new technology to work better and safer. Robots and computers do jobs like lifting and moving sheets again and again. Factories use vacuum suction systems to pick up panels without hurting them.

The table below shows how much things improve with these technologies:

|

Performance Aspect |

Improvement Observed |

|

Increase in production throughput |

|

|

Reduction in maintenance expenses |

Up to 30% |

|

Reduction in material handling damage |

|

|

Decrease in workplace safety incidents |

42% |

|

Improvement in production throughput |

23% |

Automatic Metal Steel Sheet Handler

Automatic Metal Steel Sheet Handler in Metal Processing

Vacuum Suction Panel Handlers

Vacuum suction panel handlers are very important in today’s metal factories. These machines use strong suction cups to lift steel sheets. Workers do not have to touch heavy or sharp metal. This keeps people safer and helps stop injuries. Factories use these handlers to load and unload faster. The handlers can pick up big sheets and put them on machines for cutting or welding.

Many companies get better results after using these systems.

- Automation means less rework, lower labor costs, and shorter production times.

- Advanced systems help factories do more work without losing quality.

- When factories switch from outside processing to in-house automation, they control schedules and profits better.

- One machine can do the work of many people, so workers can do other jobs.

- Some factories finish jobs up to 50% faster, so they get more orders and make more money.

Production managers use numbers to see how much things improve. The table below shows how they check efficiency:

|

Parameter |

Description |

Role in Efficiency |

|

Cycle Time (P) |

Time to process each part |

Shorter times mean more parts |

|

Setup Time (ST) |

Time for tool changes and setup |

Less setup boosts output |

|

Availability (A) |

Uptime ratio |

More uptime, less downtime |

|

Number of Parts(N) |

Total parts made in a period |

Shows real production |

|

Efficiency (E) |

Overall line efficiency |

Higher E means better output |

|

Gross Productivity |

Adjusted cycle time for losses |

Lower GP means faster work |

Efficiency Gains

Reduced Downtime

Factories that use Automatic Metal Steel Sheet Handlers have less downtime. These machines work with other equipment and watch for problems all the time. If a machine stops, the factory loses money and time. Automation helps machines run longer and fixes small issues before they get worse.

|

Metric |

Description |

Example Calculation / Benchmark |

|

Percentage of total downtime over total available production time. |

(Total Downtime / Total Available Time) x 100; e.g., (20 hrs / 720 hrs) x 100 = 2.78% |

|

|

Overall Equipment Effectiveness (OEE) |

Composite metric combining availability, performance, and quality to measure equipment utilization. |

OEE = Availability x Performance x Quality; e.g., 83.3% x 80% x 93.75% ≈ 62.5% |

|

Cost of Downtime (per hour) |

Financial cost incurred for each hour of downtime. |

$1,000 per hour (industry range $1,000 – $2,000) |

|

Impact of Downtime (monthly) |

Total monthly financial impact due to downtime. |

Example: $20,000 monthly impact |

|

Energy Consumption Per Ton |

Energy used to produce one ton of steel, indicating energy efficiency. |

Used as a KPI to assess operational improvements |

|

Yield Percentage |

Ratio of actual output to expected output, reflecting production efficiency and material utilization. |

Higher yield indicates better performance |

Factories use steps to see how much money they save. First, they find out how much unplanned downtime costs before using predictive maintenance. Next, they count how many hours of downtime they save after automation. Then, they multiply hours saved by the cost per hour to see savings. They also look for lower repair bills and longer machine life. Better energy use and higher yield are checked too.

Automatic Metal Steel Sheet Handler in metal processing helps companies cut downtime and save thousands of dollars every month.

Increased Throughput

Automation lets factories make more products in less time. Machines can work all day and night without stopping. This means more steel sheets get made, and orders are finished faster. Real-time data helps managers find slow spots and fix them fast.

|

Performance Metric |

Improvement After Automation Integration |

|

Production Output Increase |

|

|

Defect Rate Reduction |

30% (from enhanced precision) |

|

Overall Efficiency Improvement |

10% (by addressing bottlenecks via data-driven monitoring) |

- Automation lets machines work 24/7, so factories do not stop for breaks.

- Machines are very precise, so there are fewer mistakes and less waste.

- Real-time monitoring helps managers fix problems quickly.

- Companies save money because they need fewer workers and use less material.

- Shorter lead times mean customers get their orders sooner.

With these improvements, the Automatic Metal Steel Sheet Handler in metal processing helps factories make more products and stay ahead of others.

Safety and Precision

Automation makes factories safer and products better. Machines move heavy steel sheets, so workers do not have to lift or carry dangerous things. This lowers injuries and keeps people safe. Automated systems also make fewer mistakes than people.

- Automation lowers human error and keeps results steady.

- Fewer mistakes mean better quality products.

- Automated inspection systems find problems early, so factories can fix them before shipping.

- Companies spend less on labor and make more products after adding robots.

- Fewer bad products mean less waste and more profit.

Tip: Companies can check improvements by tracking defect rates, labor costs, and productivity before and after automation. Many factories see a 30% drop in labor costs and a 25% rise in productivity after using robotic systems.

Automatic Metal Steel Sheet Handler in metal processing brings safety, speed, and accuracy together. This helps factories make better products and keep workers safe.

Vacuum Suction Automatic Panel Handlers

Real-World Impact

Case Studies

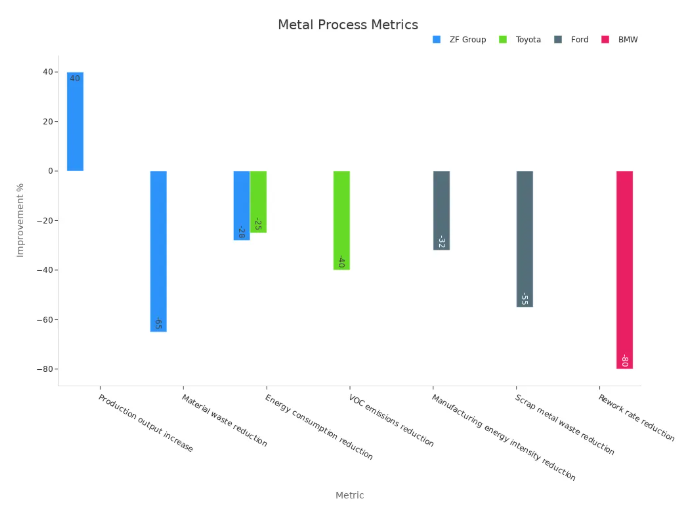

Many factories have changed a lot after using automatic metal steel sheet handlers. Companies now use numbers to see how well they are doing. For example, a US metal maker used an Advanced Planning and Scheduling system. This made lead times 30% shorter and inventory costs 20% lower. A steel plant used value stream mapping to find and remove waste. This made cycle times 25% shorter and productivity 15% higher. In Europe, a copper tubing company used Lean Six Sigma. They made 20% more products and had 30% fewer customer complaints. An Asian aluminum plant started predictive maintenance. This step made unscheduled downtime 40% less and equipment 15% more reliable.

Factories also use numbers to show their success:

|

Company |

Metric Description |

Numerical Improvement |

|

ZF Group |

Production output increase |

+40% |

|

ZF Group |

Material waste reduction |

-65% |

|

ZF Group |

Energy consumption reduction |

-28% |

|

Toyota |

VOC emissions reduction |

-40% |

|

Toyota |

Energy consumption reduction |

-25% |

|

Ford |

Manufacturing energy intensity reduction |

-32% |

|

Ford |

Scrap metal waste reduction |

-55% |

|

BMW |

Rework rate reduction |

-80% |

ERP and automation systems help companies watch scrap, labor, and machine uptime. These tools help lower rework and scrap, save money, and make products better.

Best Practices

Factories that want the best results from automation follow these steps:

- Gather data at each step to see how things work.

- Use control charts to find problems early.

- Look at the data to fix the main causes of issues.

- Clean, check, and adjust machines often.

- Use quality control software for live checks and reports.

- Teach workers how to inspect and solve problems.

- Keep tools adjusted so parts meet standards.

Tip: Companies that do these steps have fewer mistakes, less waste, and better products. They also keep machines working longer and save money.

Important measures like availability, performance, and quality help factories see their progress. Preventive maintenance, skilled workers, and smart data tools all help automation run smoothly. These best practices help companies get the most from their metal processing systems.

Automatic Metal Steel Sheet Handler in metal processing helps factories in many ways. It makes work safer for people. Factories can make more products in less time. They also save money and waste less material. Lead times get shorter, so orders are finished faster. Output rates go up, so more products are made. Quality control gets better, so there are fewer mistakes. The table below shows how automation helps:

|

KPI |

Benefit |

|

Lead Time |

Faster delivery |

|

Scrap Rate |

Less waste |

|

Output Rates |

More products made |

|

Overall Equipment Efficiency |

Machines run longer and better |

Automated systems watch machines and collect data all the time. This helps companies find new ways to save money. Many factories use these tools to keep up with changes in the industry.

FAQ

What is an automatic metal steel sheet handler?

This machine lifts, moves, and places steel sheets. It uses vacuum suction cups or robotic arms. Factories use it to make jobs faster and safer. It also helps workers do their jobs more accurately.

How does automation improve worker safety?

Automation keeps workers away from heavy or sharp steel sheets. Machines do the hard lifting and moving. This lowers the chance of injuries and accidents in the factory.

Can automatic handlers work with different sheet sizes?

Most automatic handlers can handle many sheet sizes and thicknesses. Sensors and smart controls help them pick up and move different metal sheets.

What maintenance do these machines need?

Workers check these machines often to keep them working well. They clean suction cups, check sensors, and look at moving parts. Many systems give alerts when it is time for maintenance.

How do factories measure efficiency gains?

Factories watch important numbers like cycle time, downtime, and output rates. They use tables and charts to compare before and after automation. This helps managers see if speed, safety, and costs get better.

Tip: Good records help factories find problems early and keep machines running longer.