How Cut to Length Lines Drive Efficiency in Metal Manufacturing?

Cut to length line technology changes how metal is made. It makes the cutting process faster and easier. These systems move materials by themselves. This means workers do not have to do as much. It also helps make cuts more exact. Factories that use this equipment work faster. They also make better products. Workers see less wasted material and spend less money. Precision cutting makes sure each sheet is the right size. This helps every batch turn out the same way.

Key Takeaways

· Cut to length lines make metal cutting faster. They do this by using machines instead of people. This means workers do not have to work as hard. These machines cut metal sheets very accurately. This helps use less metal and saves money. The system has important parts like uncoilers, levelers, shears, stackers, and control units. These parts all work well together. Automation makes things safer. It moves heavy coils and uses sharp tools so workers stay safe. Many industries use these lines. For example, car and building companies use them. They help make better products quickly and for less money.

What Is a Cut to Length Line?

Definition

A cut to length line is a type of machine used in metal manufacturing. It takes large coils of metal and cuts them into flat sheets of specific sizes. This process helps factories get the exact pieces they need for different products. The main goal of a cut to length line is to make sure every sheet matches the required measurements. This system improves accuracy and reduces waste. Many industries, such as construction and automotive, use these machines to speed up production and lower costs.

Factories that use cut to length lines see several benefits:

- They produce metal sheets with high precision.

- They reduce the amount of wasted material.

- They help workers finish jobs faster and with fewer mistakes.

- They support quality control by lowering the number of defective products.

- They save money on both materials and labor.

Main Components

A cut to length line has several important parts. Each part plays a key role in the process:

- Uncoiler

The uncoiler holds the large coil of metal and feeds it into the line. It keeps the coil steady and unwinds it smoothly. - Leveler

The leveler flattens the metal as it moves through the line. This step removes any bends or curves from the coil. - Shear

The shear is a cutting tool. It slices the metal into sheets of the desired length. The shear works quickly and makes clean cuts. - Stacker

The stacker collects the finished sheets and arranges them in neat piles. This makes it easy to move the sheets to the next step in production. - Control System

The control system manages the whole process. It uses computers and sensors to make sure each part works together. This system helps keep the line running smoothly and ensures every sheet meets the right size.

These components work together to create a fast, accurate, and cost-effective way to process metal. The cut to length line helps factories meet high standards for quality and efficiency.

Cut To Length Lines

How It Works

Process Steps

A cut to length line changes metal coils into flat sheets. First, the uncoiler holds the heavy coil and feeds it in. The metal goes through the leveler next. This machine makes the metal flat and smooth. Then, a feeder pushes the metal forward. The length positioning system checks the needed size for each sheet. When the metal is in place, the shear cuts it to the right length. The control system watches every step to keep things working right. At the end, the stacker puts the finished sheets in neat piles.

This process means workers do less hard work and waste less metal. Advanced controls help the line work faster and more accurately. Sensors and PLCs make sure all parts work together. The line makes metal sheets that are always the right size. Modern lines can go fast and make lots of sheets with good quality. The steps from uncoiling to stacking help stop mistakes and keep work moving well.

Automation Features

Automation is important for making cut to length lines work better. These features help factories save time and do a better job:

- Automatic feeding systems move metal coils without people.

- Rollers or conveyors help guide the metal at each step.

- Cutting blades cut the metal to the right length every time.

- Sensors look for problems and stop the line if needed.

- The system can make many cuts fast, which saves time.

- Automation helps stop waste by making sure each cut is right.

- Worker safety gets better because machines handle heavy coils and sharp tools.

Tip: Automation makes lines faster, keeps workers safe, and cuts down on waste. Factories using these features get better results and spend less money.

Cut to Length Line Benefits

Precision and Consistency

Factories need exact sizes to make customers happy. Cut to length lines help with this by using special quality control tools. These machines use straightening rollers to make sheets flat. The cutting system makes sure each sheet is the right length. Every piece comes out the same size and shape.

- Quality control checks every sheet for size and finish.

- Straightening rollers make all sheets flat and even.

- The cutting system keeps each sheet the right length.

- Fast production does not make the cuts less accurate.

- Factories get smooth, flat sheets every time.

- These lines make sheets with exact sizes, which some industries need.

- Quality control keeps every batch at a high standard.

Note: Good quality helps factories avoid mistakes and keeps customers happy.

Speed and Productivity

Factories want to work fast but keep good quality. Cut to length lines help them do this by using smart systems and tracking numbers.

- Overall Equipment Effectiveness (OEE) shows how well machines work.

- Other numbers like TEEP, OOE, AU, and OLE give more details.

- Machine Cycle Time shows how fast one sheet is made.

- Operator Cycle Time tracks how long a worker takes.

- Order Lead Time shows how fast orders get filled.

- Throughput Time is the total time from start to finish.

- Changeover Time shows how long it takes to switch jobs.

- Production Run Time and Value-Added Time show where to improve.

- Cutting Non-Value-Added Time saves money and resources.

These numbers help factories find ways to work faster and make more. Using cut to length lines helps lower costs, make more products, and keep customers happy.

Waste Reduction

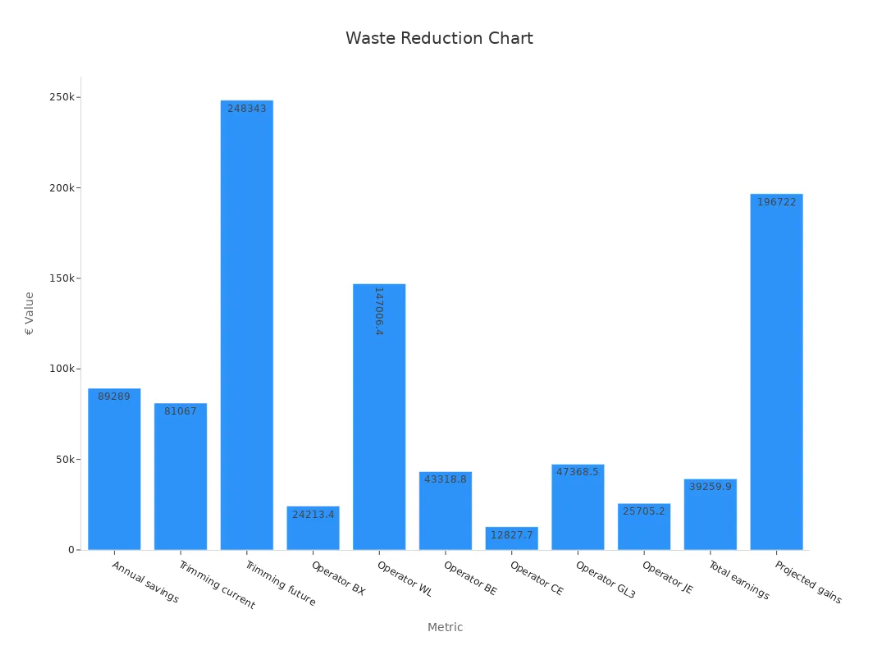

Factories lose money when they waste metal. Cut to length lines help save money by cutting waste. The table below shows how much factories can save:

|

Metric/Aspect |

Value/Impact |

|

Annual cost savings from waste minimization |

About €89,289 each year |

|

Total benefit from eliminating trimming (current + future) |

€81,067/year now; €248,343 by 2026 |

|

Monetary gain from operator reduction on various lines (until project end) |

BX: €24,213.4; WL: €147,006.4; BE: €43,318.8; CE: €12,827.7; GL3: €47,368.5; JE: €25,705.2 |

|

Total earnings (Material + Labor – Investment) |

€39,259.9 per year |

|

Gains projected until end of project (~2026) |

€196,722 |

|

Workforce impact |

0.9 fewer shifts in cable cutting and injection |

|

Assembly lines with greatest impact |

Assembly Lines V, BH, and VI |

Tip: Cutting waste saves money and helps the environment by using less.

Versatility

A cut to length line works with many metals and thicknesses. This makes it helpful for many jobs. The table below shows what makes these machines flexible:

|

Feature/Capability |

Description |

Impact on Versatility and Effectiveness |

|

Adjusts for thickness and length in real time |

Makes sure cuts are right for all thicknesses and lengths |

|

|

Quick-change tooling and modular design |

Changes fast for different metals and thicknesses |

Less downtime, works with thin aluminum (0.3mm) to thick steel (12mm+) |

|

Material compatibility |

Works with hot-rolled, cold-rolled, galvanized, stainless, aluminum, and pre-painted metals |

Handles many metal types with special controls to stop bending |

|

Tension control and leveling |

Removes stress before cutting |

Makes flat, accurate sheets without bends or buckles |

|

Programmable automation and hydraulic shears |

Gives length accuracy and needs little care |

Makes cuts precise and reliable for many metals and thicknesses |

|

High-precision circular knives and high-speed shearing |

Makes clean cuts with little waste |

Keeps surface nice for all metals, even hard stainless steel |

|

Combined slitting and cutting lines |

Does more than one job for faster work |

Makes the line faster and more flexible for different widths and thicknesses |

Factories can use these machines for many metals like hot-rolled steel, cold-rolled steel, stainless steel, and aluminum. Quick changes and smart controls help them switch jobs fast.

Quality and Safety

Factories must make safe and good products. Modern cut to length lines help them do this. For example, Thyssenkrupp Steel uses advanced machines for strong, tough sheets. Their Antwerp plant keeps supply steady and delivers fast. They also help customers with technical support.

Worthington Steel got a perfect score for quality, delivery, cost, safety, and teamwork. Their machines make laser flat sheets with good size and flatness. Automated stacking and packing keep products safe when moving and shipping. These steps help factories meet strict safety and quality rules.

Note: Good sheets and safe steps protect workers and customers. Factories using these machines can trust their products to meet industry rules.

Leveling And Cross Cutting Lines

Industry Uses

Automotive

Car makers need metal sheets that are the right size and shape. Big companies like Ford, GM, Toyota, and Volkswagen use special machines to cut steel for cars. These machines help make car parts strong and light. Lighter cars use less gas. In 2023, U.S. factories made over 3 million tons of cut steel for cars. The industry uses smart machines to check every piece. This makes sure each part meets tough rules. Car makers want to save energy and waste less. They use these systems to get good parts fast.

The car industry is growing. More companies use strong steel and new cutting machines to build better cars.

Construction

Builders use metal sheets for things like buildings and bridges. New machines help them work faster and make fewer mistakes. The table below shows how these machines help in construction:

|

Performance Indicator |

Manual Operation |

Semi-Automated Lines |

Modern Machines |

|

Average Setup Time |

240 minutes |

65 minutes |

22 minutes |

|

Hourly Throughput (22ga steel) |

75 sheets |

310 sheets |

1,700 sheets |

|

Dimensional Tolerance (±) |

0.030 inches |

0.010 inches |

0.005 inches |

|

Labor Requirement per Line |

4 operators |

2 operators |

0.5 operators |

These numbers show that new machines save time and need fewer workers. They also help builders make better products. Some companies save over $1 million each year by using these machines.

Appliances

Companies that make appliances need flat, smooth metal sheets. They use these sheets for things like fridges, ovens, and washers. Special machines cut the metal to the right size and finish. These machines help make many shapes and sizes fast. This lets companies fill big orders and keep up with new designs. The result is better quality and faster work for home and business appliances.

Custom Fabrication

Custom shops make special metal parts for many jobs. They often need small amounts or odd shapes. New cutting machines help these shops change jobs quickly. They can cut many types and thicknesses of metal. This helps them serve customers who need special parts. Shops can do more projects and give parts that fit just right.

Many industries need these machines for both big and small jobs. They help companies work faster, make better products, and stay ahead.

Cut to length line technology is changing how metal is made. These systems help factories work faster and waste less metal. They also make sure cuts are very exact. New features use smart controls and save energy. Some factories can now reach 99.2% accuracy and use less power. Experts think more people will want precision-cut steel each year until 2030. As smart tools and green ideas get better, cut to length lines will help make strong and safe products.

FAQ

What metals can a cut to length line process?

A cut to length line can handle steel, stainless steel, aluminum, and copper. Many factories use these machines for both thin and thick metal sheets. The system adjusts settings for each type of metal.

How does automation improve safety?

Automation keeps workers away from heavy coils and sharp blades. Machines move and cut the metal. Sensors stop the line if something goes wrong. This reduces the risk of injury.

Can one line handle different sheet sizes?

Yes. Operators can program the control system for many lengths and widths. The machine changes settings quickly. This helps factories fill different orders without long delays.

How often does a cut to length line need maintenance?

Most lines need regular checks every week. Operators inspect moving parts, blades, and sensors. Good maintenance keeps the machine running smoothly and prevents breakdowns.

Tip: Regular care helps the line last longer and work better.