How Metal Slitting Lines Support Sustainable Steel and Aluminum Manufacturing?

A metal Slitting line plays a vital role in sustainable steel and aluminum manufacturing. These machines cut wide coils into narrow, accurate strips. This process helps factories use materials wisely and lower waste. Precision in cutting supports high productivity and smooth operations for the next steps in production. Many manufacturers rely on this technology to meet strict quality standards and boost efficiency.

Key Takeaways

1.Metal slitting lines cut wide metal coils into precise strips, reducing waste and saving materials.

2.Automation in slitting lines boosts productivity, lowers manual labor, and improves safety.

3.Advanced slitting technology helps factories use energy efficiently and supports recycling efforts.

4.Precise cutting and real-time monitoring reduce errors and downtime, increasing overall efficiency.

5.Slitting lines play a key role in industries like automotive, construction, and electronics by providing high-quality metal strips.

Metal Slitting Line Basics

Coil to Strip Process

A metal Slitting line starts with a wide coil of steel or aluminum. The machine unwinds the coil and feeds it through a set of rotating circular knives. These knives slice the metal into several narrow strips at once. Each strip has a precise width, which matches the needs of different industries. The strips then rewind into smaller coils for easy handling and transport.

The process uses advanced features to keep the operation smooth and efficient. Automatic tension control systems adjust to the type of metal. Fast tool changes and quick threading reduce downtime. Scrap choppers and coil warehouses help manage leftover material and finished strips.

Tip: The coil-to-strip process works for many metals, including carbon steel, stainless steel, aluminum, and copper.

Here is a table showing the technical specifications for different types of metal Slitting line:

|

Gauge Type |

Max Thickness |

Max Width |

Max Coil Weight |

Max Speed (m/min) |

|

Light Gauge |

4 mm |

1800 mm |

35 tons |

500 |

|

Medium Gauge |

8 mm |

2000 mm |

40 tons |

300 |

|

Heavy Gauge |

19 mm |

2600 mm |

50 tons |

100 |

Precision and Productivity

Precision matters in every step of the slitting process. The metal Slitting line uses high-quality blades and automatic controls to keep each strip within tight width tolerances. Some machines can hold a width precision of ±0.05 mm. This accuracy means less waste and fewer rejected materials.

Modern slitting lines also boost productivity. They run at high speeds and handle heavy coils. Features like automatic tool exchange and real-time monitoring help keep the line moving. Industry 4.0 technologies, such as IoT sensors and AI-powered quality checks, allow for predictive maintenance and better quality control. These tools reduce downtime and improve output.

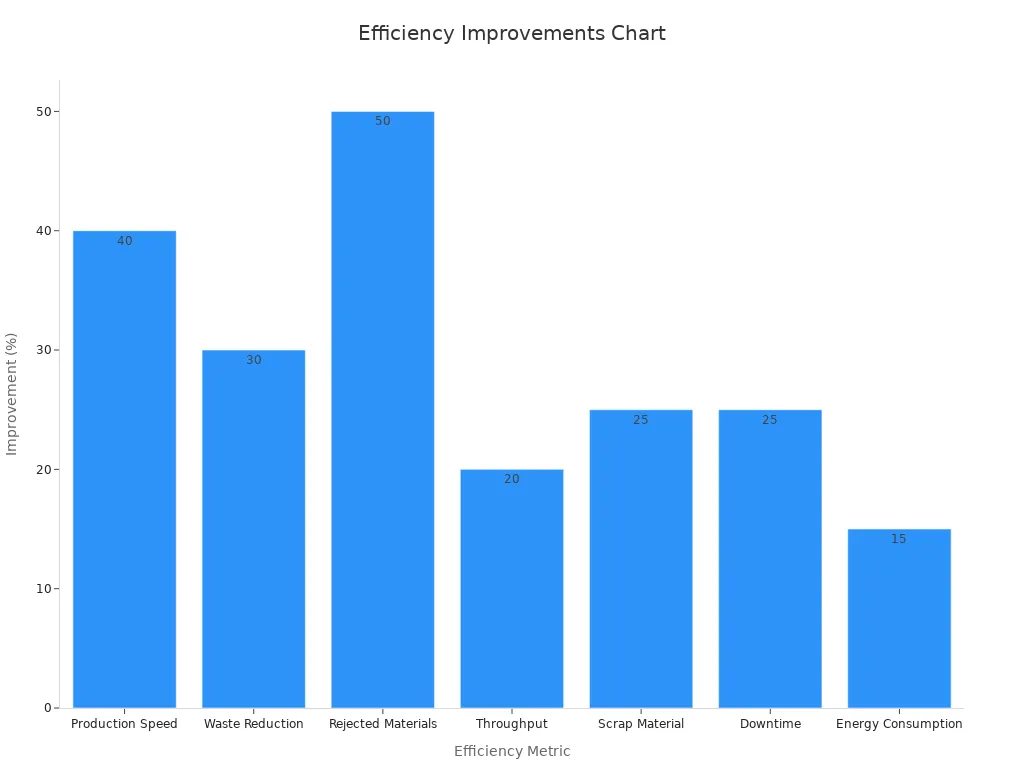

The coil-to-strip process brings clear efficiency gains. The chart below shows how production speed, waste reduction, and energy use improve with advanced slitting lines:

Efficiency Improvement Chart

These improvements help manufacturers save resources, lower costs, and support sustainable production.

Sustainability Benefits

Waste Reduction

Metal manufacturing often creates waste, but modern processes help reduce it. A metal Slitting line cuts wide coils into strips with high accuracy. This precision means factories use almost all the input material, leaving very little scrap behind. Metal spinning, a process related to slitting, also reshapes metal instead of removing it, which helps use nearly all the material in the final product. Cold-forming methods like these need less energy than heat-based ones, which supports energy conservation. Factories that use strict waste management and recycling protocols lower their environmental impact and keep manufacturing waste to a minimum.

Sustainable machining techniques also play a role. These methods reduce waste from things like cutting fluids and improve how efficiently machines work. Cleaner technologies and redesigned systems help factories meet environmental goals. By using these approaches, companies can cut down on waste and protect the environment.

Note: Reducing waste not only helps the planet but also saves money for manufacturers.

Material Optimization

Factories want to get the most out of every coil. Metal Slitting lines help by making sure each strip matches the exact size needed for the next step. This careful sizing means less leftover material and fewer rejected parts. Advanced machines use real-time monitoring and quality control to keep errors low and output high.

Here is a table showing how modern slitting lines improve performance and material use:

|

Performance Metric |

Value/Description |

|

Changeover Time |

2 to 4 minutes |

|

Maximum Cutting Speed |

Up to 400 meters per minute |

|

Maximum Number of Cuts |

Up to 60 cuts |

|

Reduction of Operator Hours |

50% reduction (approx. 4 hours saved/shift) |

|

OEE Improvement |

Increased productivity through better Overall Equipment Efficiency |

|

Precise Positioning |

Reduces errors and downtime |

|

Integrated Control Systems |

Real-time monitoring and quality control to minimize waste and improve material utilization |

Factories also benefit from features like predictive maintenance and automation. These tools keep machines running smoothly and help spot problems early. By reducing downtime and defective parts, companies save resources and improve efficiency. Automation also lowers the need for manual labor, making the process safer and faster.

1.Changeover time drops to as little as 2 minutes, sometimes overlapping with other tasks.

2.Operator hours can fall by about 50%, saving up to 4 hours per shift.

3.Precise positioning cuts down on mistakes and lost time.

4.Improved design protects the quality of slit edges and keeps material in top shape.

Recycling Support

Recycling is a key part of sustainable metal manufacturing. Metal Slitting lines make recycling easier by producing clean, uniform strips and managing scrap efficiently. Factories collect leftover pieces and send them back into the production cycle. This closed-loop system keeps valuable materials in use and reduces the need for new raw resources.

Recycling metals like aluminum brings big energy savings. Making new aluminum from recycled material uses only about 5% of the energy needed for raw production. This huge drop in energy use lowers greenhouse gas emissions and helps fight climate change. Many factories now follow strict recycling rules to make sure scraps go back into the system instead of ending up in landfills.

♻️ Recycling not only saves energy but also supports a cleaner, greener future for everyone.

Metal Slitting Line

Advancements

Automation

Automation has transformed how factories use a metal Slitting line. Machines now use advanced sensors and control systems to keep cuts precise and production fast. AI and machine learning help predict when maintenance is needed, which reduces downtime. Operators spend less time on repetitive tasks because robots handle tool changes and material movement. Automated tension control systems adjust pressure for different metals, keeping product quality high. Remote monitoring lets workers check machines from a distance and make quick changes if needed.

1.Robotic tooling changes cut downtime to less than five minutes.

2.Automated defect detection finds 95% of errors, which lowers waste.

3.Automation boosts weekly production hours by 67% and reduces setup times by over 55%.

4.Automation not only speeds up production but also makes work safer and more reliable.

Energy Efficiency

Modern slitting lines focus on saving energy. Factories use energy-efficient motors and smart controls to lower power use. Machines now optimize how much energy they need for each job. This helps reduce costs and supports green manufacturing goals. Many lines use real-time data to adjust speed and tension, which saves even more energy. Eco-friendly practices, such as waste minimization and recycling, also help factories meet sustainability targets.

1.Energy-efficient coil slitting lines lower operational costs.

2.Advanced software solutions optimize scheduling and reduce unnecessary energy use.

3.Recycling leftover metal saves resources and cuts emissions.

Safety Features

Safety remains a top priority in metal processing. New slitting lines include features that protect workers and equipment. Automatic slowdown systems prevent material damage and accidents. Safety interlocks stop the machine if someone opens a guard or door. Robotic handling reduces the need for workers to move heavy coils, which lowers the risk of injury. Remote diagnostics let technicians fix problems without being near moving parts.

1.Robotic automation reduces ergonomic risks and workplace injuries.

2.Intuitive operator interfaces make machines easier and safer to use.

3.Real-time monitoring helps spot hazards before they cause harm.

🛡️ Modern safety features keep workers safe and help factories maintain high-quality production.

Slitting Machine

Industry Impact

Construction

The construction industry uses steel strips for beams, panels, and frames. Slitting lines provide the exact widths needed for each project. This precision cuts material waste by up to 15%. Builders can finish projects faster because automated lines boost production capacity by up to 40%. Compliance with safety and environmental standards, such as OSHA and CE, keeps workers safe and supports green building goals. As cities grow, construction companies rely on these technologies to meet the rising need for new buildings and infrastructure.

1.Accurate slitting supports strong, reliable structures.

2.Reduced waste lowers costs and helps the environment.

Electronics

Electronics manufacturers need thin, uniform strips of copper and aluminum for wiring, batteries, and circuit boards. Slitting lines deliver these materials with high speed and accuracy. Real-time monitoring tools, like visual management systems, help factories increase daily output by up to 30%. Downtime drops by 94% when operators can see and fix problems quickly. Some lines achieve a return on investment in just a few days by raising throughput from 70% to 98%. These gains support the fast growth of electric vehicles and consumer electronics.

|

Improvement Metric |

Measured Value |

Description |

|

OEE Improvement |

Real-time data helps reduce downtime |

|

|

Production Increase |

Up to 30% |

More units produced each day |

|

Downtime Reduction |

94% |

Less time lost to machine stops |

|

ROI |

100% in 2-3 days |

Fast payback from higher throughput |

|

Target Rate Achievement |

127% of plan |

Exceeding planned production goals |

⚡ Electronics and EV markets depend on slitting lines for reliable, high-quality components.

Metal slitting lines help manufacturers achieve high efficiency and sustainability in steel and aluminum production. These machines use advanced cutting technology to reduce waste and improve accuracy. Factories see less downtime and higher throughput.

1.Precision cutting lowers scrap rates and supports consistent product quality.

2.Automation increases productivity and reduces manual labor.

3.Improved safety features extend machine life and support long-term operations.

By choosing advanced slitting solutions, companies can meet both environmental and business goals.

FAQ

What is a metal slitting line?

A metal slitting line is a machine that cuts wide coils of metal into narrow strips. Factories use these strips for making cars, buildings, and electronics. The process helps save material and reduce waste.

How do slitting lines help the environment?

Slitting lines use precise cutting to lower scrap rates. Factories recycle leftover pieces. This process saves energy and keeps more metal in use. Companies can meet green goals and protect natural resources.

Can slitting lines handle different metals?

Yes, slitting lines work with steel, aluminum, copper, and other metals. Operators adjust the machine for each type. This flexibility supports many industries and products.

Why is automation important in slitting lines?

Automation speeds up production and improves safety. Robots handle heavy coils and tool changes. Sensors check quality in real time. Workers spend less time on risky tasks.

What safety features do modern slitting lines include?

Modern slitting lines use safety guards, emergency stops, and automatic slowdown systems. Robotic arms move heavy materials. These features protect workers and keep the factory safe.