How to Select the Best Aluminum Coil Slitting Machine for Your Needs?

Choosing the right aluminum coil slitting machine affects your whole production process. If you pick a machine with smart sensors and automation, you can waste less material by up to 12%. This helps you spend less money on materials and disposal. Automation lets you make coils with steady quality and fewer mistakes. You also pay less for workers and work faster. Energy-saving designs help you follow environmental rules and save money. Your choice changes your product quality and your profits.

Key Takeaways

- Pick a slitting machine that fits your aluminum type. Make sure it works with your coil size and thickness. This helps you get clean cuts and less waste.

- Find machines with smart controls and automation. These features make the work faster and more accurate. They also help lower labor costs.

- Take care of your machine and its blades often. This keeps the machine working well for a long time.

- Choose a supplier with a good name and strong support. Make sure they offer a good warranty to keep your money safe.

- Teach your team how to use the machine safely. Good training helps stop accidents and makes better products.

Slitting Process

What It Involves

You need to understand each step in the slitting process to get the best results. The process follows a clear order:

- Inspect and prepare the aluminum coils. Check the size, surface, and strength. Remove packaging and clean the edges.

- Load the coil onto a decoiler. Unwind the coil smoothly to avoid tension problems.

- Pass the strip through pinch-roll levelers. This step removes bends and makes the strip flat.

- Feed the strip into the slitter head. Rotary knives cut the coil into narrow strips. You must watch and adjust the blades to keep the width correct.

- Control the tension and form loops. This keeps the strips even and prevents defects.

- Rewind the slit strips onto recoilers. Match the recoiling speed with the slitting speed. Inspect the new coils for quality.

- Test and inspect the final product. Check the width, thickness, edge, and surface before packaging.

Tip: Careful inspection at each step helps you avoid costly mistakes later.

Why It Matters

The slitting process affects how well you can use the aluminum coils. If you do not handle the coils properly, you may see many types of damage. The table below shows common problems and their effects:

Aluminum is soft and easy to bend. Scratches or dents can ruin the coil. The slit edges are weak and can break if you do not protect them. You should use soft packaging and control the tension during recoiling. This keeps the coils strong and ready for your next steps.

Buying Factors

Material Compatibility

First, check if the aluminum coil slitting machine works with your aluminum type. Some machines are better for certain alloys or tempers. If you use both cold rolled and hot rolled aluminum, pick a machine that can do both. The machine should help control burrs, surface problems, and camber. These features help you get clean and straight strips.

Coil Size & Thickness

You need to match the machine’s specs to your needs. Look at the coil’s width and thickness. The right machine will handle your biggest and smallest coils. Here is a table to compare common ranges:

Most machines can cut thicknesses from 0.2 mm to 6.0 mm. They can also cut widths from 100 mm to 2000 mm. Some machines can even handle rolls up to 2650 mm wide. Always check the biggest coil thickness and width your machine can handle. Thicker coils need stronger machines with more power. Thinner coils let you run faster and use less energy.

- Thicker coils need more cutting power and stronger bending tools.

- Thick materials may limit how narrow you can cut and can hurt edge quality.

- Thin coils let you cut faster and use material better.

- Think about your future needs. If you want to cut thicker or wider coils later, pick a machine that can grow with you.

Slit Quality & Precision

You want every strip to be the right width and have smooth edges. Good slit quality means less waste and better products. Industry rules need tight width limits and burrs under 5%. Machines with smart controls help you keep cuts clean and even. Look for features like:

- Tight width limits for stamping or CNC machines.

- Burr control for smooth and safe edges.

- Precise slitter arbor clearance for the best edges.

- Smart systems that adjust speed, blade angle, and tension.

Makers use sharp, high-quality blades and check cuts with special tools. They also use roller leveling to keep strips flat. Keeping blades sharp and checking the machine helps it stay accurate. Many companies use ISO 9001:2015 certification to show their quality.

Tip: Good slit quality means less waste and saves money.

Speed & Automation

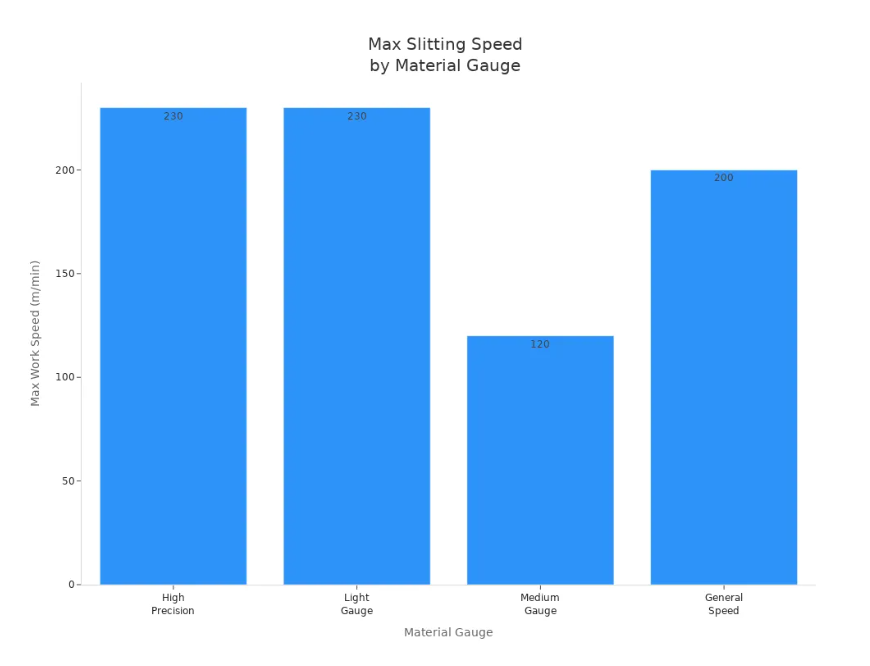

Speed is important if you want to make more coils fast. Most modern machines run at 60 to 150 meters per minute. Some high-precision machines can go up to 230 meters per minute, especially with thin coils.

Automation makes your job easier. Automated machines cut more accurately and faster. They also need fewer workers. You can move workers to other jobs and make fewer mistakes. Automation helps you change tools quickly and keep the machine running longer. Some systems let you run the machine without anyone there, which saves time and money.

Durability & Maintenance

A good machine should last many years. Check for problems like dull blades, rollers that are not straight, or loose bearings. These problems can cause bad cuts, noise, or even machine breakdowns. Regular care keeps your machine working well. You should:

- Replace or sharpen blades often.

- Check and align rollers.

- Oil moving parts.

- Tighten bolts and check bearings.

Pick a machine that is easy to take care of. Look for models with easy-to-reach parts and good help from the maker. Easy care means less downtime and more steady work.

Space & Facility Needs

Make sure the machine fits in your workspace. Big machines can handle bigger coils and more work, but they need more space. Measure your building and plan before you buy. The machine should fit into your line without blocking other tools. A good fit helps you move materials easily and keeps your work smooth.

Note: Always match the machine size to your work and space for the best results.

Aluminum Coil Slitting Machine Types

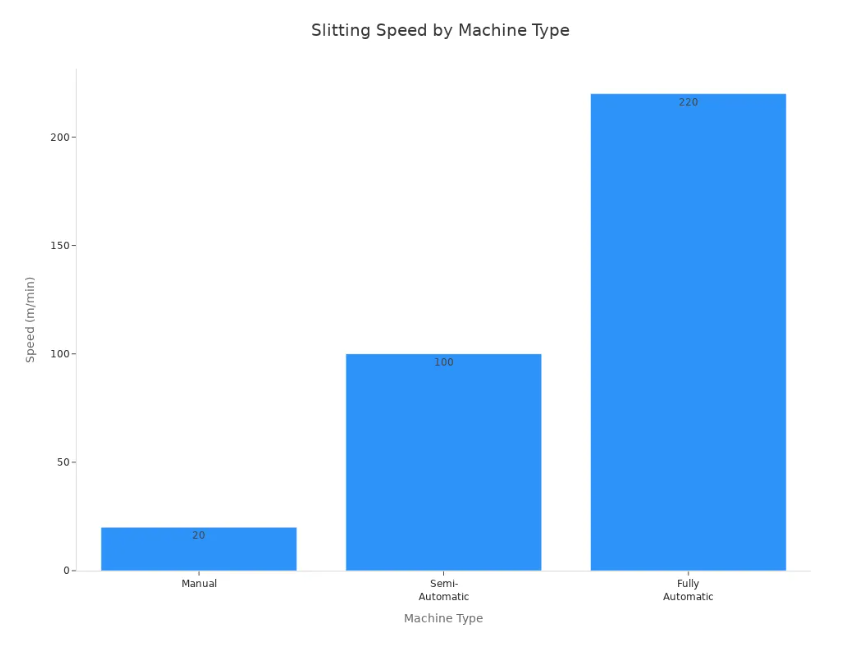

Manual

Manual slitting machines need you to do everything by hand. You must load the coils and set the blades yourself. You also adjust tension without help from the machine. These machines work well for small jobs or when you change setups a lot. Manual machines cost less at first, but you need more workers. They run slower and do not cut as accurately. You can use many coil types, but you must check the quality often.

Semi-Automatic

Semi-automatic machines use some automation to help you work faster. The machine helps control tension and fix mistakes. You still load coils and change blades by hand. The machine helps with speed and makes cuts more accurate. Semi-automatic machines are good for medium-sized jobs. You get better precision, usually within ±0.2mm. They run faster, up to 120 meters per minute. You need fewer workers than with manual machines.

Fully Automatic

Fully automatic machines use computers to control almost every step. You can load coils and set blade widths with buttons. The machine controls tension and checks quality by itself. These machines work best in big factories that need fast and perfect cuts. They give the highest precision, often within ±0.05mm. They run very fast, over 200 meters per minute. The machine changes tools and checks quality on its own. You need fewer workers, but they must be trained well. Maintenance is harder, but you get less downtime and more output.

Note: Fully automatic machines can run all day and night. They have little downtime, but you need skilled workers for maintenance.

Application Fit

Pick the machine type that matches your needs. Think about how much you make, coil size, thickness, and space. If you have a small shop, a manual or small machine may be best. For medium jobs, semi-automatic machines balance cost and speed. Big factories with high precision should use fully automatic machines. Features like automatic tension control and laser inspection help you get better results. They also help you waste less material. Always check your coil size and quality needs before you choose a machine.

Key Features

Control Systems

A good control system makes your work easier and better. Many top machines have a touchscreen you can use. You can set speed, tension, and cutting with a few taps. Modern systems use PLCs and watch the machine in real time. These controls help you avoid mistakes and keep cuts right. Automation lets you run fast and change coil types quickly. You get less waste and more good coils. The system also saves space and keeps downtime short.

- Touchscreen controls make setup simple

- Real-time monitoring finds problems fast

- Automatic changes for speed and tension

Tip: Smart controls help you keep quality high and mistakes low.

Safety

Safety is very important when using this machine. New machines use smart sensors to keep you safe. These sensors stop the machine if something is wrong. For example, if a coil is not in the right spot, the machine stops. Load cells keep tension steady to protect the coil and machine. Automation means workers do not need to be near moving parts. This lowers the chance of accidents. Real-time data helps you see problems before they get worse.

- Sensors stop unsafe actions

- Automation keeps workers away from danger

- Data helps make maintenance safer

Tooling Options

The right tooling options help you do more and get better results. Ultra-precision slitting heads with auto blade locks give clean, straight cuts. Automatic tooling change systems let you switch setups fast. Tool robots can change blades for you, making things quicker. Thickness inspection systems check your material as you work. You always know your quality. Quick-change mandrels and separator shafts help you adjust for different coil sizes fast.

Note: Good tooling options help you work with many aluminum types and strip widths.

Customization

You might need special features for your work. Many machines let you pick custom widths for your projects. This helps you waste less and save money. You can choose light, medium, or heavy-duty machines for your coil thickness. Some machines have extra blade platforms for quick width changes. You can add scrap winders, special recoiling units, or energy-saving parts. Custom control panels make the machine easy to use. Many suppliers help you pick the best setup for your needs.

- Custom widths for special projects

- Less waste with exact sizes

- Choices for different coil thicknesses

- Special features for your industry

- Support for setup and use

Customization helps your machine fit your business, not the other way around.

Supplier Evaluation

Reputation

You should pick a supplier people trust. A good supplier helps you feel safe and get better results. There are some things to look for when you check a supplier. If they have worked in the industry for many years, they are likely reliable. Certifications like ISO show they care about quality. Machines with new technology can help your business do well. Good customer service means you get help when you need it. Fair prices help you save money and still get good machines. If a supplier can make special changes for you, that is a good sign. You can use the internet, talk to industry groups, or ask others for advice to find the best supplier.

Tip: Suppliers with a strong reputation usually have good reviews and many customers who come back.

Support & Parts

You need a supplier who gives good support and spare parts. The best suppliers help you set up, train your team, and fix problems. This keeps your aluminum coil slitting machine working well. Ask if they have spare parts ready and how fast they can send them. Fast help means your machine does not stop for long.

- Quick answers to your questions

- Help at your place for setup and repairs

- Training for your workers

- Spare parts ready when you need them

Warranty

A warranty helps protect your money. Different suppliers give different warranty times and services. Some give one year, others give two years. Some include free spare parts and help for life. You might get help with setup and training, but you may need to pay for travel and work time.

Note: Always check the warranty before you buy. A longer warranty and extra help can save you money on repairs.

Customer Feedback

Customer feedback shows how a supplier treats buyers. Read reviews and ask for other customers’ opinions. Happy customers talk about fast help, easy setup, and good machines. Look for comments about honesty and how the supplier fixes problems. You can find reviews online or ask other businesses for advice.

- Good reviews mean good service

- Honest feedback helps you avoid trouble

- Advice from other buyers builds trust

Listening to what other customers say helps you pick the best supplier for your aluminum coil slitting machine.

Maintenance Tips

Routine Care

You should take care of your machine often. Clean the blades after each shift. Use gentle cleaners and soft brushes. This gets rid of dirt and stops rust. Check blades for chips or cracks often. This helps you avoid long stops. Lubricate blades every few hours with special oil. This lowers heat and friction. Keep blades dry and covered to stop rust and scratches. Sharpen blades based on the metal you cut. Hard metals need sharpening every 100-150 hours. Softer metals like aluminum need sharpening every 200-300 hours.

Other important steps are:

- Change hydraulic oil and filters every 600 hours.

- Check hydraulic lines and seals between 600 and 2,000 hours.

- Lubricate motor shaft bearings every 2,000 hours.

- Clean motors and cabinet filters every 2,000 hours.

- Check clutch, brake, and ball screws often.

- Watch gearbox oil and temperature every 1,000 hours.

- Calibrate sensors every 2,000 hours.

- Check safety fences and curtains every 500 hours.

Regular care helps blades last longer and keeps your machine safe.

Training

Training your team is very important. Teach them how to use the machine safely. Show them how to check slit strips with measuring tools. Tell them to keep records for tracking. Teach them how to set up blades and machine settings. Remind them to secure coils and not lift heavy coils by hand. Always use blade guards. Never adjust blades while the machine is running. Make sure everyone knows what to do in emergencies. Teach them to use the emergency stop and report problems.

Training helps your team work safely and make good products. Well-trained workers can find problems early and fix them fast.

Downtime Reduction

Smart systems help you work faster and avoid delays. The table below shows some ways to do this:

Using these systems helps you avoid delays and keeps your machine working well.

You should make sure your machine fits your business needs. Try to get good quality and accurate cuts. This helps you save money and do better work. If your supplier is helpful, you can fix problems fast.

- Think about what you need before you buy.

- Talk to suppliers you trust or ask for a demo.

Picking the right Aluminum coil slitting machine helps your business get bigger and makes your products better.

FAQ

What is the main benefit of using an automatic aluminum coil slitting machine?

You can make coils faster and more accurately. Automatic machines help you make fewer mistakes. They also save money because you need fewer workers. You can finish bigger jobs with less work.

How often should you sharpen the slitting blades?

Check the blades after each shift. Sharpen them every 200 to 300 hours for aluminum. Dull blades make rough edges and waste material. Always read the machine manual for the best advice.

Can one machine handle different aluminum alloys?

Yes, most new machines can work with many aluminum alloys. You need to change blade settings and tension for each alloy. Always check if your machine works with the alloy before you start.

What safety features should you look for?

Find machines with emergency stop buttons, safety fences, and sensors. These features help keep you safe from accidents. Automatic tension control also protects the machine while it works.