How to Select the Right Precision Slitting Machinefor Your Metal Processing Needs?

To choose the right Precision Slitting Machine for metal processing, it’s essential to align the machine’s capabilities with your specific material type. Consider factors like thickness, production volume, and desired quality. According to the CNC Slitting Machine Market report, selecting the appropriate Precision Slitting Machine for metal processing can improve factory efficiency by 27%. Choosing the wrong machine, however, can lead to significant issues:

- Bearings may wear out prematurely, causing a loss of accuracy.

- Edge trimming might be ineffective, resulting in material waste.

- Outdated systems can pose safety risks.

- Problems with coil tension, machine vibrations, and power failures can occur.

- You may end up with rough edges, burrs, and poor-quality material.

Always evaluate your current needs and anticipate future requirements to ensure long-term success with your Precision Slitting Machine for metal processing.

Key Takeaways

- Pick a slitting machine that fits your material type. Make sure it works with your material thickness. Check if it can handle your production amount. This helps you get good quality and work faster.

- Choose the right slitting method for your job. Use the best blades for clean cuts. This helps you waste less metal. It is important for different metals and thicknesses.

- Find machines with strong automation. Good tension control is important. Safety features help keep your team safe. These things help you finish work faster.

- Think about the full cost of the machine. Look at the starting price and how much it costs to run. Check if the supplier gives good help. This helps you save money over time.

- Take care of your machine often. Follow safety and quality rules in your industry. This helps your machine last longer. It also keeps your workplace safe.

Requirements Analysis

Material Type & Thickness

When picking a Precision Slitting Machine for metal processing, you need to think about what kind of material you will use. The thickness of the material is also important. Different materials, like plastic film, paper, or metal sheet, act in their own ways. These differences change how the machine cuts and moves the material. For example:

- Soft things like plastic films might need antistatic parts, especially for electronics.

- Hard metals need blades that do not wear out fast to keep the edges nice.

- Laminated packaging needs to be protected on the surface when being cut.

You should make sure the machine can cut the thickness of your material. Most machines work with thicknesses from 0.02 mm to 10 mm. If you use the wrong thickness, you could break the material or the machine. Always check if the machine fits what you use now and what you might use later. Machines that work with many types and thicknesses are better for the future and save money on upgrades.

Tip: Pick a machine with blades you can swap and tension control. This helps you work with different materials and keep cuts neat.

Slit Width & Tolerance

Slit width and tolerance are very important for good product quality. You need to make sure the machine can meet your width and thickness needs. Here are some tables with normal industry standards:

|

Material Thickness Range (inches) |

Typical Width Tolerance (inches) |

|

±0.005 – ±0.010 |

|

|

0.026 – 0.060 |

±0.010 – ±0.015 |

|

0.061 – 0.125 |

±0.015 – ±0.020 |

|

0.126 – 0.250 |

±0.020 – ±0.030 |

|

Parameter |

Range / Tolerance |

|

Thickness Range |

|

|

Thickness Tolerance |

±0.01mm (normal), ±0.002mm (precision) |

|

Width Range |

1.50mm – 600mm |

|

Width Tolerance |

±0.10mm (normal), ±0.02mm (precision) |

New machines can cut slit widths from 0.200 inches up to 48 inches. Fast slitting lines with razor slitters can keep tight tolerances. This is important for industries like automotive and aerospace. In these jobs, you may need tolerances as close as ±0.005″ to ±0.015″ for safety and performance. Things like blade sharpness, how you set up the machine, coil flatness, and camber all change the final tolerance.

Note: Tighter tolerances mean less waste and better products, which is very important for high-precision jobs.

Production Volume

How much you need to make affects what kind of slitting machine you should get. If you need to make a lot, it is smart to buy a fully automated machine. These machines cost more at first but save money over time. They also work faster and are more efficient.

- Making a lot of products makes it worth spending on special tools and setup.

- If you only make a few, semi-automated or manual machines cost less. They are cheaper to set up and let you change things easily.

- You can finish jobs faster if you do not need special setups or tools.

If you think your needs might grow, pick a machine that can handle more work later. Machines that can do many jobs help you take new orders without buying a new machine.

Power & Speed

Power and speed decide how fast and well you can cut materials. A normal Precision Slitting Machine for metal processing uses about 3.5 kW and can go up to 160 meters per minute. More power lets you cut thicker materials and do bigger jobs. But too much power can make things too hot and cause problems, so you need to balance power and speed for your job.

|

Parameter |

Typical Specification |

|

Power |

3.5 kW |

|

Maximum Slitting Speed |

0-160 m/min |

Faster cutting means you finish jobs quicker and make more products. Good engineering keeps cuts accurate even at high speeds, so you waste less. Machines built well last longer, need fewer repairs, and save money. Companies using good machines often see their work go up by 25%.

Tip: Pick a machine with good safety features and automation. These make work faster and keep workers safe.

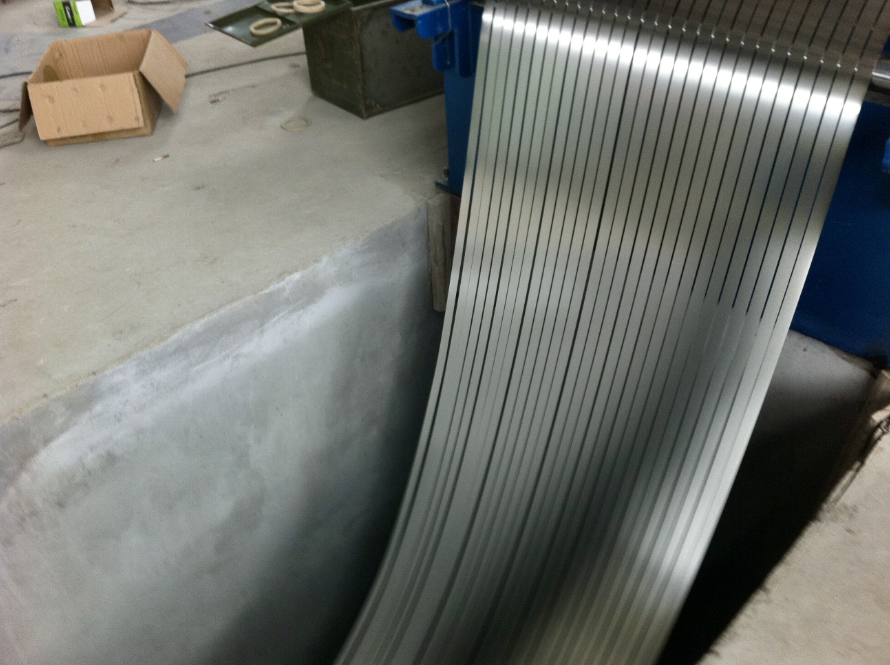

Precision Slitting Machine for Metal Processing

Slitting Methods

You have to pick the right slitting method for your material. Each method is best for certain jobs. Razor slitting uses sharp spinning blades. This works well for thin and bendy things like films and plastics. It does not work for thick or rough metals. Shear slitting uses two round blades that cut like scissors. This is good for thick and heavy materials like metal sheets, foils, and laminates. Shear slitting gives very exact cuts and can handle changes in thickness. Rotary or crush slitting pushes a blade against a hard roller. This works for thick, tough, or sticky materials but does not cut as neatly.

|

Slitting Method |

Best For |

Advantages |

Disadvantages |

|

Razor |

Thin, light materials (films, plastics) |

Easy setup, clean cuts |

Not for thick metals, more heat |

|

Shear |

Thick, dense materials (metal sheets, foils) |

Precise, less heat |

Higher cost, needs careful setup |

|

Rotary/Crush |

Thick, tough materials (rubber, laminates) |

Simple, handles tough jobs |

Less precise, more dust |

Tip: For most metal jobs, shear slitting in a Precision Slitting Machine for metal processing works best.

Blade Selection

The blade you pick changes how smooth your cut is and how many burrs you get. Sharp blades need less force and make smoother edges. Dull or badly shaped blades make more burrs and can hurt your material. The shape of the blade, like the angle, changes how sharp and strong it is. Small angles are sharper but wear out faster. Big angles last longer but may not cut as clean. Good blade materials, like tungsten carbide, stay sharp longer and make fewer burrs. You should check blades often for damage or dullness. Clean and oil them to stop rust. Sharpen blades on a schedule and change them if they break.

- Use precision blades with tight tolerances for even, clean cuts.

- Keep blades sharp to lower burrs and skip extra work.

- Store blades in dry, safe spots to stop rust.

Note: Taking care of blades in your Precision Slitting Machine for metal processing gives better edges and less waste.

Machine Flexibility

A flexible Precision Slitting Machine for metal processing can work with many metal types and thicknesses. Find machines with decoilers that move sideways and control tension. These help keep coils steady and stop edge damage. Expansion core shafts let you change coil sizes without problems. Precision levelers flatten metal plates for better cuts. Double slitter devices let you cut thin strips and change widths. Good tension control keeps things steady, even when rolls get smaller. Computer controls make it easy to change jobs fast. Automation helps stop mistakes and keeps workers safe.

- Strong rotary knives cut steel, stainless steel, aluminum, and alloys.

- Blades you can adjust let you pick different slit widths.

- Scrap devices handle waste and keep your area tidy.

Tip: Pick a Precision Slitting Machine for metal processing with these features to handle new jobs and cut down on stops.

Key Features

Automation

Today, automation changes how you use a Precision Slitting Machine for metal processing. These new features help you work faster and more accurately. Many machines now have:

- Touchscreen controls show live data and let you change settings easily.

- Automated knife positioning saves time and lines up blades perfectly.

- Servo drive systems give you exact control and use less power.

- Quick-change blade holders help you switch materials fast.

- Built-in quality control checks the slitting process and warns you about problems.

- Remote monitoring and alerts tell you when to fix things before they break.

Automation helps you make fewer mistakes, get better products, and work faster. You can also link your machine to planning systems for easier tracking and reports.

Tension Control

Tension control is very important for making good slit metal. You must keep the right pull on the metal strip when you unwind, cut, and rewind it. Good tension control stops wrinkles, scratches, and wavy edges. This keeps your metal flat and looking nice, which matters for how it works and looks.

When you use a Precision Slitting Machine for metal processing with good tension control, you get:

- Fewer mistakes and less wasted material.

- Easier coil handling and fewer breaks.

- Faster work and less waiting for repairs.

- Safer work and machines that last longer.

Keeping tension steady means your finished products always meet tough rules.

Safety Features

Safety is always the most important thing in metal processing. The best machines have many ways to keep you and your team safe:

- Emergency stop buttons are easy to reach if you need them.

- Safety interlocks stop the machine if guards are not closed.

- Protective guards cover moving parts to stop injuries.

- Sensors and alarms warn you about jams or if things get too hot.

- Check the machine before using it to make sure it is safe.

- Wear gloves, glasses, and ear protection to stay safe.

- Use the right tools to lift and move coils.

- Keep up with regular care and check blades often.

- Follow clear rules and keep learning about safety.

A good safety system keeps everyone safe and helps you avoid accidents that cost money.

Cost & Value

Initial Investment

When you want to buy a precision slitting machine for metal processing, you should think about how much it costs at first. The Fabricator says most new small or medium precision slitting lines cost from $300,000 to $600,000. These machines can cut metal that is 24 to 60 inches wide. They come ready with pipes and wires, so you do not need much extra work to set them up. This price helps you know what to expect if you want to do slitting in your own shop. You also need to save money for putting the machine in, teaching workers, and adding any special parts you want.

Tip: Buying a good machine at the start can help you spend less on fixing or changing it later.

Operating Costs

After you buy the machine, you will still have to pay for some things. You need to pay for power, new blades, regular care, and workers. You might also pay for new software or more safety gear. If your machine has a lot of automation, you can pay less for workers and make fewer mistakes. Machines that use less power and have strong blades help you save money each month.

Here is a simple table of common operating costs:

|

Cost Type |

Description |

|

Energy |

Power needed to run the machine |

|

Blades |

Replacement and sharpening |

|

Maintenance |

Regular checks and repairs |

|

Labor |

Operator wages and training |

|

Consumables |

Lubricants, cleaning supplies |

ROI

You want your money to help your business. A good precision slitting machine lets you waste less, make better products, and finish jobs faster. You can take more orders and finish them on time. Over time, you will save money because you throw away less and fix things less often. Many companies get back the money they spent in two to five years, depending on how much they make and how well the machine works.

Picking the right machine helps you earn more and stay ahead of others.

Supplier Support

Reputation

Pick a supplier with a strong reputation. A good supplier helps you avoid problems. They keep your work going without stops. Use these things to check if a supplier is good:

- Quality: See if the supplier uses strict quality rules like ISO 9001. Ask for reports and samples to check the quality yourself.

- Capacity: Make sure the supplier can fill your order. Check if they can finish on time. Look at how much they make and what they have in stock.

- Risks: Check if the supplier is open about money and delivery. Good suppliers have plans for problems and follow all rules.

- Costs and Pricing: Look at all costs, not just the price to buy. Think about running, fixing, and upgrading the machine to see if it fits your budget.

- Manufacturer and Supplier Considerations: Think about how much experience the supplier has. Check if they help after you buy, give technical support, and talk clearly.

A supplier with a good reputation helps you feel safe and helps your business grow.

After-Sales Service

After-sales service is just as important as the machine. You want a supplier who helps you after you buy. Look for these helpful services:

- Free replacement parts

- Video help from experts

- Online help for fast answers

- Repairs and care at your place

- Help setting up the machine

You also get more from suppliers who offer:

- Fast and helpful service

- Account managers who know your work

- Skilled staff who speak clear English

- A focus on your happiness and working together for a long time

Good after-sales service keeps your machine working and stops long breaks.

Training

Training helps you use your precision slitting machine the right way. Top suppliers give training that teaches you how to use and care for the machine. Training has both lessons and hands-on practice. Experts change the training to fit your needs, so your team learns what works best for your machine. Suppliers also give you clear manuals and online help. With good training, your team can fix problems fast and keep the machine working well. This help stops mistakes and makes your machine last longer.

Training from your supplier makes your team stronger and keeps your machine safe.

Compliance & Maintenance

Industry Standards

You need to make sure your equipment follows important industry rules. These rules keep workers safe and help you get good results. Some top certifications are ISO 9001 for quality, ISO 14001 for the environment, and ISO 45001 for safety at work. If you work in aerospace or need very exact machines, you also need AS9100. In India, you must look for BIS Scheme X Certification and Indian Standards like IS 15491:2004 for CNC machines.

|

Description |

Applicability to Metal Processing Machines |

|

|

ISO 9001 |

Quality management system for consistent results and process control |

Ensures reliable, high-quality production |

|

ISO 14001 |

Environmental management for sustainable manufacturing |

Promotes eco-friendly machine production |

|

ISO 45001 |

Occupational health and safety management |

Protects workers and reduces workplace injuries |

|

AS9100 |

Specialized quality standard for aerospace and high-precision industries |

Required for CNC-based and ultra-precision equipment |

|

BIS Scheme X Certification |

Mandatory Indian certification for machine tool safety and reliability |

Applies to slitting, cutting, and CNC machines |

You should also follow OSHA and ANSI/ISO 12100:2012 safety rules. These rules say you need safety guards, emergency stop buttons, and regular checks for risks. Train your team and keep records to show you follow the rules and pass checks.

Tip: Getting certified helps customers trust you and lets you sell in more places.

Regular Maintenance

Taking care of your Precision Slitting Machine for metal processing keeps it safe and working well. Every day, check fluids, oil moving parts, and wipe the machine clean. Each week, look at bearings, belts, and wires to make sure they are okay. Once a month, do a deep clean and check every part. Every year, have a skilled technician do a full check and fix anything broken.

|

Key Tasks and Focus Areas |

|

|

Daily |

Check fluids, lubricate, clean surfaces |

|

Weekly |

Inspect bearings, belts, electrical connections |

|

Monthly |

Deep clean and inspect all machine components |

|

Annual |

Full inspection and repairs by professionals |

If you follow a good maintenance plan, your machine will break less and last longer. You will keep your cuts neat and your team safe. Always use real parts and teach workers to spot problems early. Checking bolts, hoses, and seals often stops big problems and keeps everyone safe.

Taking care of your machine helps it stay accurate and keeps your workplace safe.

Picking the right precision slitting machine means you need to look at a few important things. First, think about what kind of material you have, how thick it is, and how much you need to make. Next, pick the slitting method and machine features that fit your job best. You should also check if the machine has good automation, tension control, and safety parts. Remember to think about how much it will cost over time, how easy it is to fix, and if the supplier will help you later. Make sure the machine follows all the rules for your industry.

Good suppliers help you find a machine that works for what you need now and in the future. If you want a machine made just for you and help after you buy it, talk to an expert who can look at what you need.

FAQ

What materials can a precision slitting machine handle?

A precision slitting machine can cut many metals. These include steel, aluminum, copper, and alloys. Some machines also work with plastic films or laminates. Always check the machine’s details to see what it can cut. Make sure it matches your material and thickness.

How often should you maintain your slitting machine?

You need to check your machine every day. Inspect it each week and clean it deeply once a month. Every year, have a professional look at it. Doing regular care keeps your machine safe and working well.

Can you upgrade your slitting machine later?

Many precision slitting machines let you add upgrades. You can get more automation, new blades, or better controls. Ask your supplier about upgrades before you buy your machine.

What safety features should you look for?

You should look for emergency stop buttons and safety guards. Interlocks help keep the machine safe. Sensors and alarms warn you about problems. Good machines also have clear safety rules and need proper training for workers.