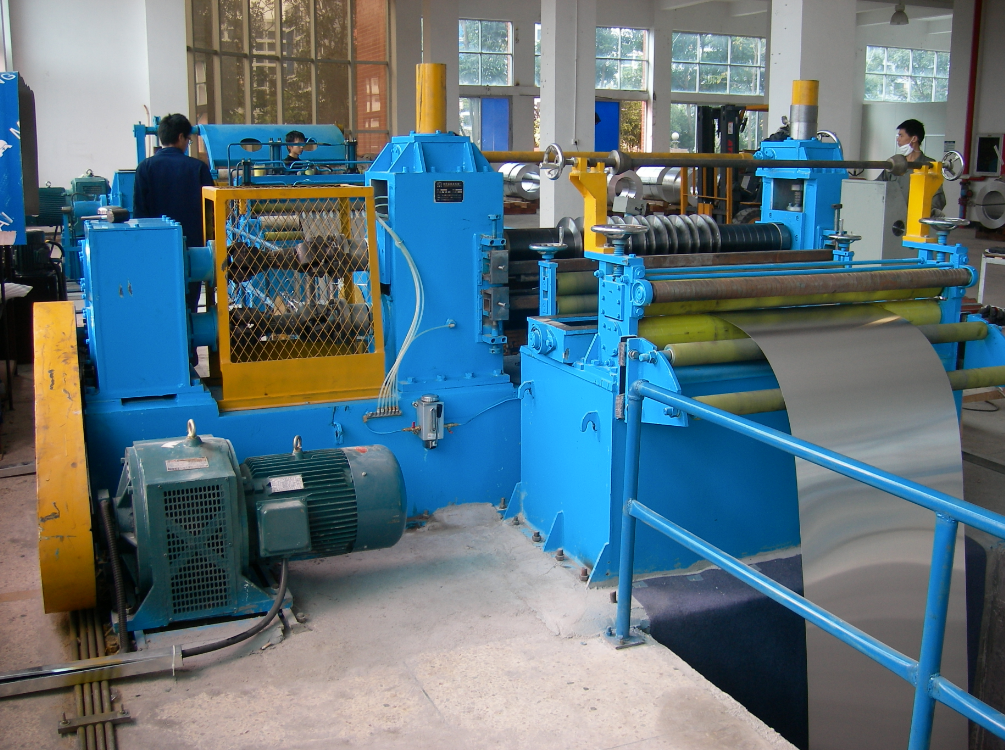

Key Differences Between Semi-Automatic and Automatic Slitting Machines

You can see clear differences between semi-automatic vs automatic slitting machines. These differences affect your spending, work speed, and the number of workers required.

- Semi-automatic machines help you work faster and maintain a clean area, which enhances the quality of your products.

- On the other hand, automatic machines allow for even greater speed and require fewer workers. This means you can produce more items and cut fabric with greater precision.

When choosing between semi-automatic vs automatic slitting machines, consider your daily production needs and whether you need to ship products quickly.

Key Takeaways

- Semi-automatic slitting machines let people control some parts. They also use some automation. These machines work well for medium-sized jobs.

- Automatic slitting machines work fast and are very efficient. They can make more products with fewer workers. These machines are best for big jobs.

- Think about how much you need to make and your budget. Automatic machines cost more at first. But they can help you save money later.

- Teach your team how to use the machine. This helps keep everyone safe. It also helps work go smoothly.

- Look at the materials you will use and how you need to cut them. This helps you pick the right machine for your business.

Semi-Automatic Slitting Machines

Operation

Semi-automatic slitting machines use both manual and automatic steps. You have to set up the machine and put the material in by hand. The machine then cuts the material using motors and sensors. You control when the machine starts and stops. Sometimes, you need to change the settings while it works. This gives you more control than a fully automatic machine.

Here is a table that shows how semi-automatic machines compare to other types:

Semi-automatic machines are in the middle of these two choices. They work faster than manual machines. They also give you more control than automatic ones.

Labor Involvement

You are important when using a semi-automatic slitting machine. You must load the materials and watch the process. Sometimes, you take out the finished rolls. The machine does the cutting part. You need to pay attention and be ready to make changes. You do not need as many workers as with manual machines. But you still need trained people. This helps you save money on workers and keep production fast.

Tip: Teaching your team how to use semi-automatic machines can make work safer and help you get more done.

Use Cases

Many industries use semi-automatic slitting machines. These machines are good when you need to be flexible and work at a medium speed. For example, textile companies use them to cut fabric rolls into smaller pieces. This helps get materials ready for the next steps.

Here is a table that shows common uses:

You might pick a semi-automatic machine if you want both manual and automatic features. When you compare semi-automatic and automatic slitting machines, think about how much you need to make and how much control you want.

Automatic Slitting Machines

Automation Level

Automatic slitting machines have a lot of automation. They use smart control systems built into the machine. You can set them up to feed, cut, and unload by themselves. Most models have winding and unwinding turrets that work on their own. This helps you switch materials fast and keeps the machine running. The line does not stop for long. Here is a table that shows the main features of automation in these machines:

Automatic slitting machines help you work faster and stop less.

Labor Needs

Automatic slitting machines need fewer workers. The machine does almost everything for you. You do not have to load or unload by hand. The system keeps things moving and makes fewer mistakes. Here is a table that compares labor needs between manual and automatic slitting machines:

Your team can do other jobs while the machine works. This is a big difference between semi-automatic and automatic slitting machines.

Applications

Many industries use automatic slitting machines. These machines are good for big jobs that need speed and accuracy. Some common uses are:

- Packaging industry

- Printing industry

- Textiles industry

- Electronics industry

- Paper industry

- Film manufacturing

- Metalworking industry

You can cut paper, film, fabric, or metal into exact sizes. Automatic slitting machines help you make a lot of products and keep the results the same every time.

Semi-Automatic vs Automatic Slitting Machines

Automation

When you look at semi-automatic and automatic slitting machines, automation is a big difference. Automatic machines do almost everything for you. They feed, slit, wind, and check for mistakes with little help. Semi-automatic machines need you to do some jobs by hand. You have to load material and change settings yourself. Here is a table that shows how each type works:

If you want less work and more speed, automatic machines are better.

Efficiency

Efficiency is very different between semi-automatic and automatic slitting machines. Automatic machines can make three times more products. They keep your work moving and help stop mistakes. You get more items in less time, and the quality stays good. Here are some ways automation helps efficiency:

- Automatic machines make more products, up to 300% more.

- They help you work faster and keep quality steady.

- You see fewer mistakes and more even results.

Most factories pick automatic machines because they are faster and more exact. Semi-automatic machines are quicker than manual ones, but not as fast or accurate as automatic machines.

Labor

Labor needs are not the same for semi-automatic and automatic slitting machines. Semi-automatic machines need more skilled workers. You must load materials, watch the process, and take out finished rolls. This means you pay more for workers and need more training. Automatic machines need fewer people. One person can run many machines at once. This can lower your worker count by four or five. You can use saved workers for other jobs, making your whole team work better.

Note: Automatic machines help you spend less on workers and let your team do other important jobs.

Cost

Cost is a big thing to think about. Automatic machines cost more to buy and fix. But they save you money later by using fewer workers and wasting less material. For example, cutting edges neatly and using motors that save energy lowers your bills and waste. One company wasted 18% less material after using a dual-shaft slitter. Semi-automatic machines cost less at first and have simple parts, but you might spend more on workers and waste over time.

Maintenance

Maintenance is different for semi-automatic and automatic slitting machines. Semi-automatic machines have simple parts. Most problems can be fixed by you or your team with little training. Yearly maintenance costs are low, about 2% of the machine’s value. Automatic machines have more complex systems. You need special skills to fix them. Parts cost more, and you must check the machine often. Yearly maintenance can be 5%-8% of the price, and changing main parts can cost up to 20% of the machine’s value.

Suitability

Picking between semi-automatic and automatic slitting machines depends on what you need to make. Semi-automatic machines are best for medium businesses with normal production. You get more control and can change products easily. Automatic machines are best for big jobs. If you need to make lots of items fast and keep quality high, automatic machines are the best choice.

When you choose, think about blade types, the material you use, how long blades last, and how fast you need to work. The right machine helps you save money, make better products, and reach your goals.

Pros and Cons

Semi-Automatic

If you use a semi-automatic slitting machine, you can control the process more. You can change the settings fast. It is easy to work with different materials. These machines cost less to buy and fix. You do not need special skills to use them. Training your team does not take much time.

Pros:

- You can control the process and make changes when needed.

- The cost to buy and fix is lower.

- Workers can learn how to use it easily.

- It works well for small and medium jobs.

Cons:

- It is slower and not as steady as automatic systems.

- Workers can get tired after long hours.

- Mistakes can happen and hurt the quality.

- It is hard to make more products without more automation.

Note: Experts say semi-automatic machines can make workers tired and cause mistakes. It can also be hard to make more products with these machines.

Automatic

Automatic slitting machines help you work faster and make fewer mistakes. You can set up the machine and let it run by itself. These machines keep your work steady and correct. You need fewer workers, so you save money. Automatic machines are good for big orders and tight schedules.

Tip: If you want to make more products and have fewer mistakes, automatic machines are a good choice when picking between semi-automatic vs automatic slitting machines.

Choosing the Right Machine

Production Needs

First, think about what you want to make. If you need to make a lot of items, pick a fully automatic slitting machine. It helps you work fast and meet big orders. If you make a medium amount, a semi-automatic machine works well. The kind of material you use is important too. Some materials need special ways to cut or extra care. Here are some things to remember:

- Automatic machines are best for big jobs and fast work.

- Semi-automatic machines are good for medium jobs and save money.

- Some materials need different ways to be cut.

Budget

Your money matters when you choose a machine. You want a machine that saves money over time, not just one that is cheap now. Some automatic machines cost more at first. But they help you spend less on repairs and work stops. Cheaper automatic machines can help you work better without spending too much.

- Cheaper automatic machines help you save money.

- They let you make more products without spending a lot.

Workforce

Think about your workers. Semi-automatic machines need people to load materials and watch the process. Automatic machines need less help. One worker can run many machines. This lets your team do other jobs. If you have a small team, an automatic machine may be best.

Tip: Teaching your team to use the right machine can make work safer and help them do more.

Application

Pick a machine that fits your job. Ask yourself these questions:

- What materials will you cut?

- How many items do you need to make?

- What cutting style works best?

- Do you need very exact cuts and strong machines?

Semi-automatic machines are good for flexible jobs and small batches. Automatic machines are best for making lots of items. When you choose between semi-automatic and automatic slitting machines, think about your materials, how much you need to make, and how much automation you want.

When you look at semi-automatic and automatic slitting machines, you notice big differences. Automatic machines work faster and keep the quality the same each time. They do not need as many workers, but they cost more money and need skilled people to fix them. Semi-automatic machines let you control more steps and change things easily. They cost less and are easier to take care of.

To pick the right machine, think about how much you need to make, how much money you have, and what your team can do. Make sure the machine fits your business needs so you get the best results.

FAQ

What is the main difference between semi-automatic and automatic slitting machines?

You control more steps with a semi-automatic machine. An automatic machine does most tasks by itself. Automatic machines work faster and need less help from you.

Do automatic slitting machines need skilled workers?

You do not need many workers for automatic machines. You need at least one person who knows how to set up and fix the machine. Training helps your team use the machine safely.

Can I use both types of machines for the same materials?

Yes, you can use both machines for many materials like paper, film, or fabric. Check the machine’s guide to make sure it fits your material and job size.

How do I choose the right slitting machine for my business?

Think about how much you need to make, your budget, and your team’s skills.

- Pick automatic for big jobs and speed.

- Choose semi-automatic for more control and lower cost.