Why Automation Is Essential for Modern Metal Tube and Plate Processing

Automation now drives success in metal tube and plate processing industries. Companies see a 40% boost in productivity and lower production costs when they automate. They also achieve higher product quality and fewer errors. Intelligent Automated Warehouse applicable to metal tube and plate processing industries helps teams manage heavy materials safely and efficiently. Automated systems deliver consistent data, flag mistakes early, and keep operations running smoothly. These advances make automation the key to staying ahead in a tough market.

Businesses that use automation handle complex tasks faster and safer, gaining a real edge over competitors.

Key Takeaways

1.Automation boosts productivity by speeding up operations and cutting setup times by over half, helping companies fill more orders faster.

2.Smart automated systems reduce errors and waste by detecting defects early, making workplaces safer and products more reliable.

3.Intelligent automated warehouses improve inventory tracking and space use, saving time and reducing mistakes in handling heavy materials.

4.Flexible automation adapts to changing demands and custom orders, allowing companies to grow and meet customer needs efficiently.

5.Real-time data from automated systems helps managers fix problems quickly, maintain high quality, and make smarter decisions.

Efficiency Gains

Faster Operations

Automation transforms metal tube and plate processing by making every step faster. Machines set up jobs in less than half the time compared to manual methods. The following table shows how automation slashes set-up and lead times:

|

Time Reduction Context |

Percentage Reduction |

|

Set-up times with technical improvements |

|

|

Average set-up time reduction with mixed strategies |

59% |

|

Fraction of overall set-up time reduction due to technical improvements |

84% |

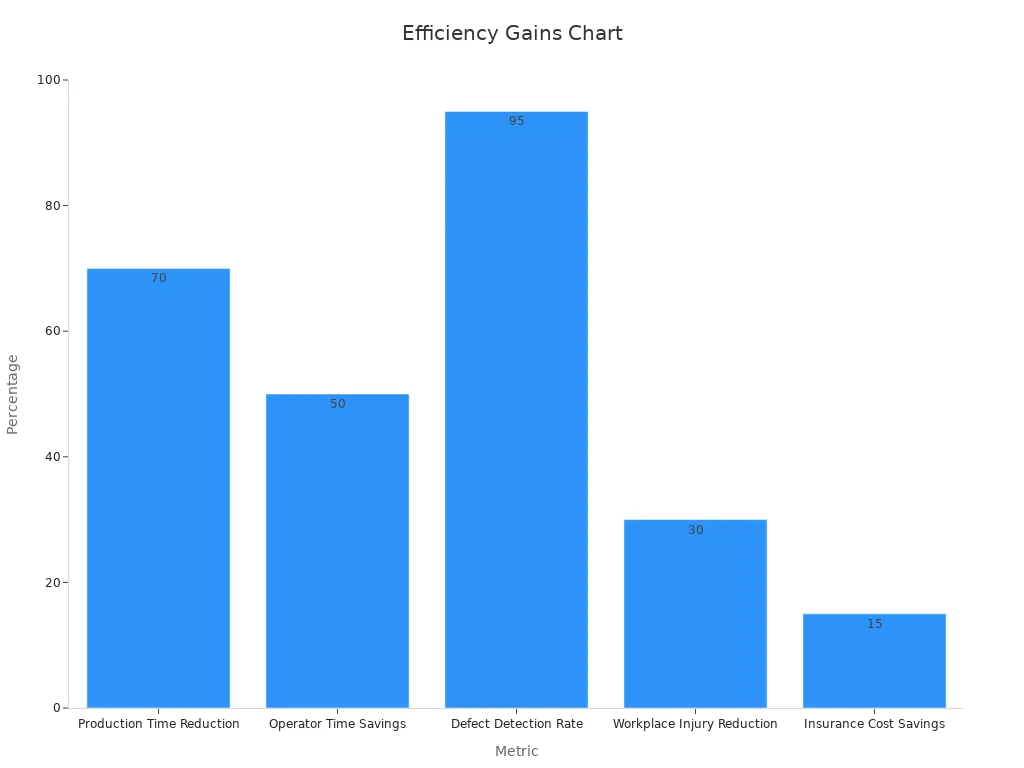

Automated systems also boost weekly production hours by 67%. Companies see lead times drop by up to 50% when automation is fully integrated. These gains mean more orders filled and less waiting for customers. The chart below highlights the dramatic improvements in production time, operator time, and other key metrics:

Automation frees up skilled workers. Operators spend 50% less time on repetitive tasks, allowing them to focus on higher-value work. Companies like Reynders have seen these benefits firsthand, with faster workflows and better organization.

Reduced Errors

Automated systems use smart sensors and process controls to catch mistakes early. These systems monitor thickness, heat, and chemical composition in real time. When something goes wrong, the system adjusts or stops production to prevent defects. This approach leads to a 95% defect detection rate and much less waste.

1.Robotic automation eliminates repetitive motion injuries and reduces ergonomic risks.

2.Workers avoid burns, strains, and other hazards.

3.Fewer injuries mean fewer mistakes and higher product quality.

Automation ensures every product meets strict standards. Companies see fewer reworks and less scrap. The result is a safer workplace, lower costs, and happier customers. Automation does not just speed up production—it makes every part better.

Intelligent Automated Warehouse for Metal Tube and Plate Processing Industries

Inventory Management

Intelligent Automated Warehouse applicable to metal tube and plate processing industries changes how companies handle inventory. These systems track every piece of metal as it enters, moves, or leaves the warehouse. Workers no longer need to count or search for materials by hand. The warehouse uses smart software and sensors to update inventory in real time. This means managers always know what is in stock and where to find it.

Automated warehouses also make order picking and packaging much faster. Robots and conveyors move heavy tubes and plates to the right place. Workers spend less time lifting and more time on important tasks. Companies see fewer mistakes in orders because the system checks each step. This leads to happier customers and fewer returns.

Prima Power’s automated storage solutions show how these systems work in real factories. Their Fast Loading Storage System and Combo Tower Storage help companies keep track of every item. These solutions connect directly to production lines, so materials move smoothly from storage to machines. As a result, companies save time, reduce costs, and boost productivity.

Real-time inventory data helps managers make smart decisions. They can order new materials before running out, avoid overstock, and plan production better.

Intelligent Automated Warehouse

Space Utilization

Space matters in metal tube and plate processing. Bulky materials take up a lot of room. Intelligent Automated Warehouse applicable to metal tube and plate processing industries uses vertical storage and smart layouts to fit more materials in less space. Companies can store more tubes and plates without building bigger warehouses.

Automated systems organize materials by size, type, or job order. This makes it easy to find and move what is needed. The warehouse software plans the best routes for robots and conveyors, so nothing gets in the way. Workers stay safe because machines handle the heavy lifting.

Prima Power’s Night Train FMS® and Combo Laser Tower show how companies can increase storage capacity and run longer without stopping. These systems allow for long unmanned operation cycles. Companies use their space better and keep production running, even at night.

1.Companies save money by using less floor space.

2.They avoid clutter and keep the warehouse safe.

3.Smart layouts mean faster loading and unloading.

Intelligent Automated Warehouse applicable to metal tube and plate processing industries gives companies a clear view of their space and materials. Managers can see where every item is stored and how much space is left. This helps them plan for growth and handle big orders with ease.

Companies that use intelligent automated warehouses stay ahead. They work faster, use space better, and make smarter choices every day.

Flexibility and Scalability

Adapting to Demand

Modern metal tube and plate processing companies face changing customer needs every day. Flexible and scalable automation systems help these companies adjust quickly. They can start with small automation projects and expand as their business grows. This stepwise approach fits different budgets and needs.

1.Flexible systems deliver top performance even when the environment changes.

2.Companies can add new modules or features as their operations evolve.

3.Automation adapts to different production volumes by running more machines in parallel.

Tube laser technology, for example, works well for both small and large jobs. It keeps efficiency and precision high, no matter the project size. Automation also reduces manual work, which lowers labor costs and boosts productivity. Companies that invest in scalable automation stay ready for future changes in the market.

Automated systems cut handling time in sheet metal bending by up to 50%. Energy use drops by as much as 80% with smart hydraulics. These systems also improve safety with advanced sensors. Real-world results show companies halving lead times and increasing output without hiring more staff. Skilled workers can focus on important tasks, not repetitive ones.

Flexible automation gives companies the power to meet demand spikes and stay competitive.

Supporting Customization

Customers often want unique parts or special designs. Automated systems make it easy to handle diverse orders and custom requests. These systems use smart software to program machines for different cutting, bending, or punching needs.

|

Feature Category |

Description |

|

One program works for laser, plasma, waterjet, and punch machines. |

|

|

Sector-Specific Support |

Special software handles complex tube profiles and multi-axis cutting. |

|

ERP/MRP Integration |

Real-time updates connect inventory, orders, and production planning. |

|

Real-Time Production Tracking |

Managers see job progress and machine status instantly. |

|

Automatic Part Recognition |

Machines set up quickly and cut parts with high accuracy. |

|

Operator Instructions |

Auto-generated guides reduce mistakes and keep quality high. |

Automated quality checks adjust operations to ensure every part meets exact specs. Uniform machine interfaces help operators learn quickly and manage many machines at once. Companies can handle custom orders faster and with fewer errors. Advanced programming tools process 3D models and generate toolpaths for custom parts. Integration with business systems keeps production smooth from order to delivery.

Companies that use flexible automation can say “yes” to more customers and deliver exactly what they want—every time.

Smart AS/RS

![]() Quality and Data Control

Quality and Data Control

Improved Quality Assurance

Automated systems raise the bar for quality in metal tube and plate processing. Companies that use automation see fewer mistakes and more consistent results. Machines do not get tired or distracted, so every product meets the same high standards.

1.Automation reduces human error and cuts down on defects.

2.Advanced sensors and machine vision check each product in real time.

3.Closed-loop control systems use sensor feedback to fix errors as they happen.

4.Automation delivers high repeatability and accuracy, so every batch looks the same.

5.Fewer defects mean fewer recalls and happier customers.

6.Integrated sensors, controllers, and actuators keep the process stable and precise.

Quality control does not stop at the machines. Companies follow strict industry standards and track every step of production. They use clear inspection policies and keep detailed records. This approach builds trust and keeps customers coming back.

1. Companies meet standards like ASME Section 9 and AWS D1.1 for welding and fabrication. 2. They document inspections, welding procedures, and material handling. 3. Automated inspection and statistical process control keep quality on track. 4. Quality control manuals get regular updates to meet new rules. 5. Clear communication between customer and fabricator ensures reliability. 6. Metrics like throughput and error rates show how well automation works. 7. Detailed records and photos provide full traceability.

Automated quality assurance gives companies a strong reputation for reliability and excellence.

Real-Time Data

Real-time data changes how companies make decisions. Machines collect and analyze information every second. Managers see what happens on the shop floor right away. This instant feedback helps them fix problems before they grow.

|

Evidence Aspect |

Description |

|

Sensors in forming tools track forces during bending, giving live updates on the process. |

|

|

Correlation with quality |

Data links forming forces to product quality, predicting issues before they happen. |

|

Validation methods |

Tests and simulations confirm the accuracy of these measurements. |

|

Immediate feedback application |

Inline feedback lets systems adjust settings instantly, reducing defects. |

|

Impact on decision-making |

Adaptive control helps managers act fast, improving quality and reducing waste. |

|

Industry 4.0 context |

Real-time analytics support process optimization and predictive maintenance. |

Companies that use real-time data stay ahead. They spot trends, prevent downtime, and deliver better products. Smart automation turns information into action, driving success in every project.

Automation shapes the future of metal tube and plate processing. Companies gain speed, accuracy, and safer workplaces. The RoboHarsh project shows that robotic solutions boost productivity and protect workers. IKEA’s drone study proves that intelligent automated warehouse applicable to metal tube and plate processing industries improves safety and job satisfaction. Businesses that invest in these systems stay ahead of the competition. FOT Machinery offers solutions that help companies grow. Now is the time to embrace smart automation and lead the industry.

FAQ

What are the main benefits of automation in metal tube and plate processing?

Automation increases speed, accuracy, and safety. Companies see fewer errors and lower costs. Automated systems help businesses stay competitive and meet customer demands faster.

How does an intelligent automated warehouse improve inventory management?

Real-time tracking gives managers instant updates. Automated systems reduce lost materials and speed up order picking. Companies avoid overstock and shortages, making smarter decisions every day.

Can automation handle custom orders and small batches?

Yes! Automated machines adjust quickly for different jobs. They process custom designs and small batches with high precision. Companies deliver unique products without slowing down production.

Is automation safe for workers?

Automated systems reduce heavy lifting and repetitive tasks. Workers avoid injuries and stay safer on the job. Companies create a healthier workplace and boost employee satisfaction.

How can a company start with automation?

1.Assess current processes.

2.Identify repetitive or risky tasks.

3.Choose scalable automation solutions.

4.Train staff for new roles.

Companies that invest early gain a strong advantage in the market.